13 tools

Hedge and tree maintenance

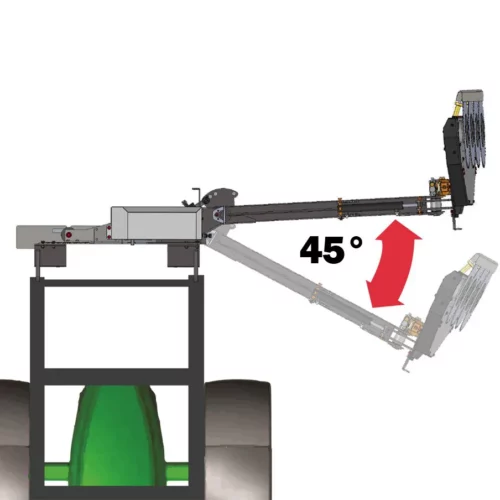

45°

Automatic Hydraulic Security

40-50 l/min

Minimum oil flow required for vehicle

2-years warranty

High quality materials that ensure a long life

Overview

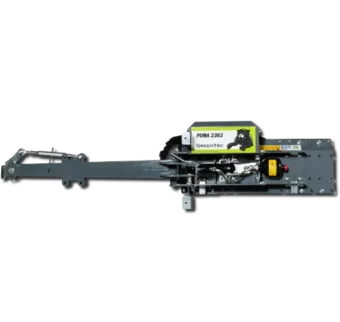

Multi Carrier HXF 3302 Tele

Our Multi Carrier HXF 3302 Tele offers great flexibility as you can adjust the arm to the terrain. It is an ideal solution for working in conditions with limited space, such as forest tracks, bike paths and orchards.

The Multi Carrier HXF 3302 Tele is the largest model in the HXF series and is mainly mounted on telehandlers, large front end loaders and excavators. An extensive range of tools for hedge cutting and tree trimming can quickly be attached or detached to the frame.

Powerful features

Protects the machine from overloading when cutting large material

Control the machine from the cabin of your vehicle. No risk of branches falling on your vehicle

Utilize your vehicle throughout the season and switch quickly between tools

Quick jump to

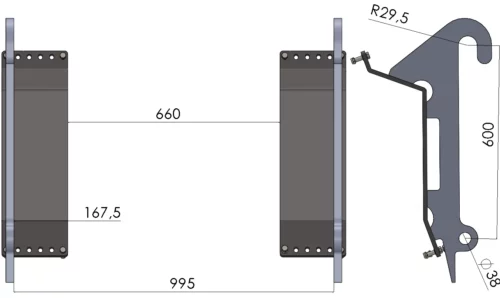

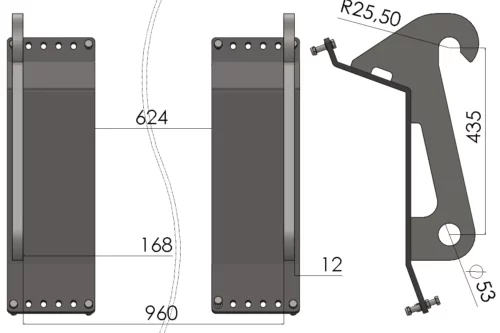

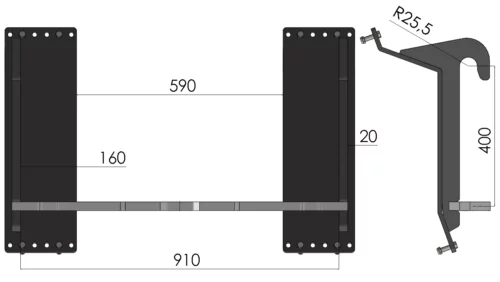

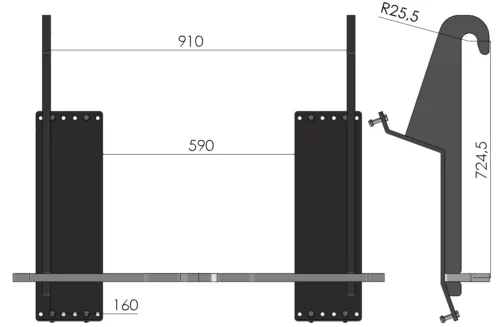

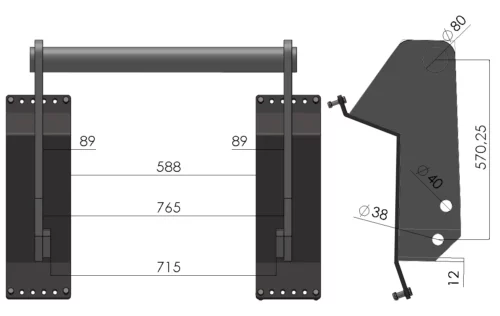

Specifications

HXF 3302 Tele

| Reach from center of vehicle to end of tool |

1.6-2.5 m

|

5'3"-8'2"

|

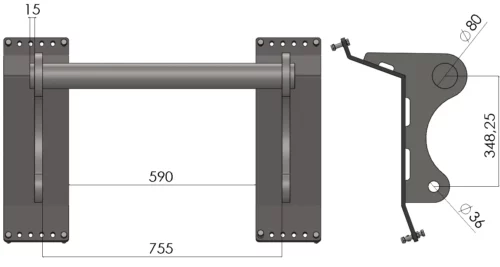

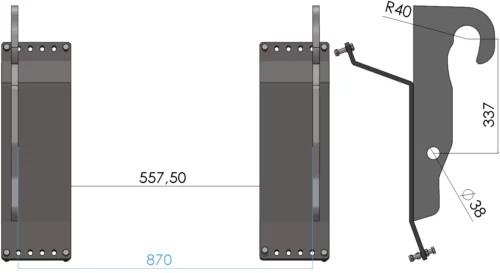

| Transport width |

2.5 m

|

8'2"

|

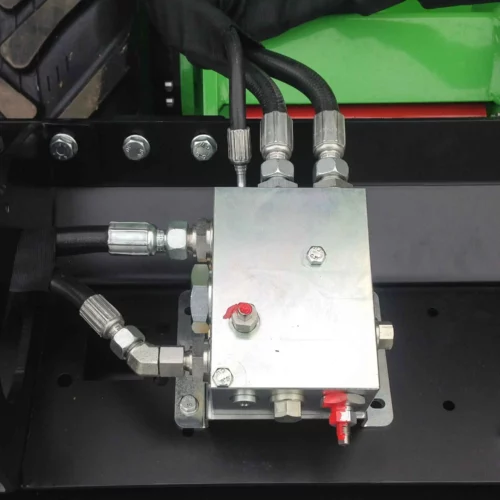

| Required hydraulic connections |

1 x double acting + 1 x drain

|

|

| Standard oil flow |

50 l/min @ 180 bar

|

13.2 gpm @ 2611 psi

|

| Alternative oil flow |

40 l/min @ 180 bar

|

10.6 gpm @ 2611 psi

|

| Weight without brackets |

230 kg

|

507 lb

|

Under the hood

HXF 3302 Tele

Hydraulic cutting angle control

Change cutting angle on the go

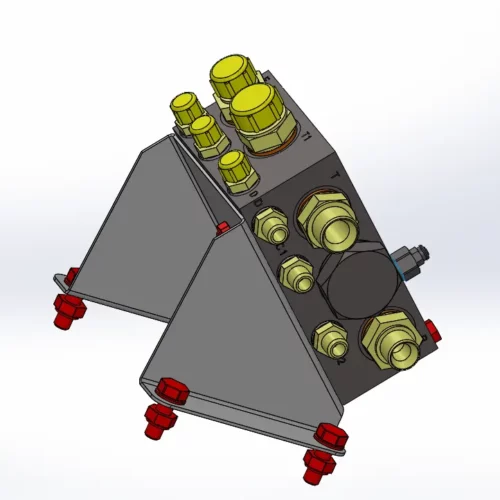

Oil flow divider

Longer life for the oil engine

Automatic break-back system

The arm goes backwards if too much pressure is applied from the cutting objective

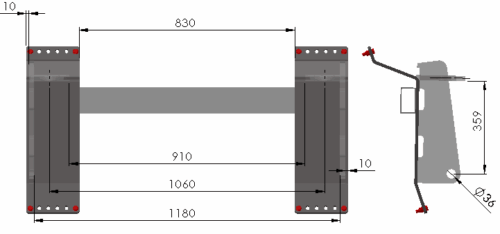

Counterweights

Stabilize the weight between the HXF 3302 Tele and your vehicle

Flexible arm

Increase or decrease the working width of the arm

Right and left versions

The HXF 3302 Tele is available in right and left versions

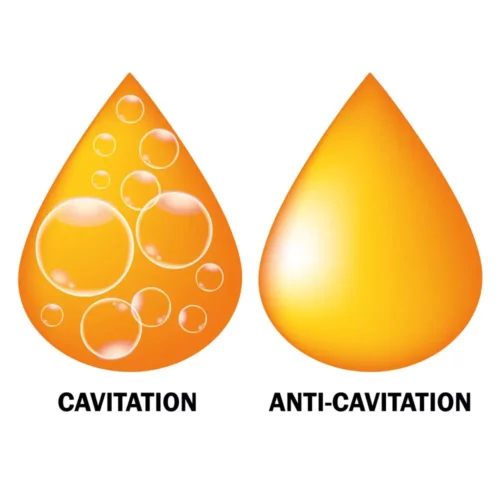

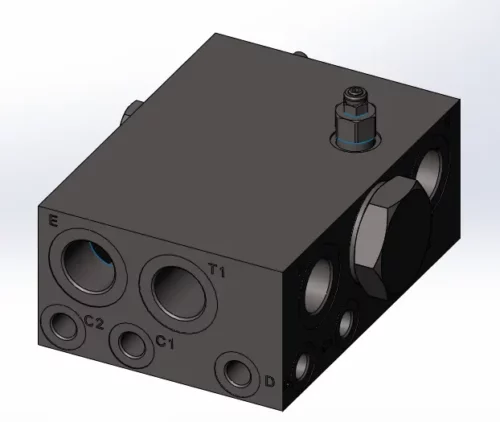

Anti-cavitation valve

Minimize the risk of cavitation damage in connection with insufficient inlet pressure

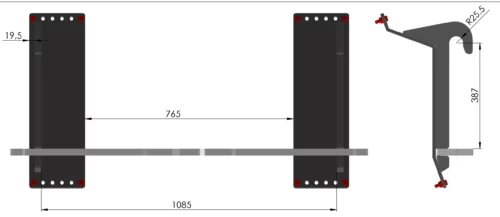

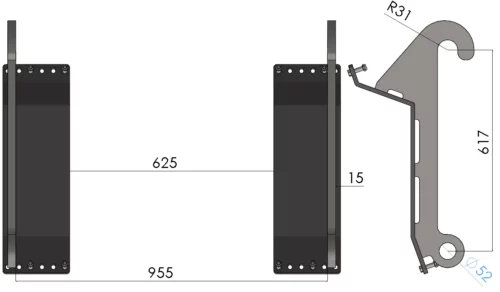

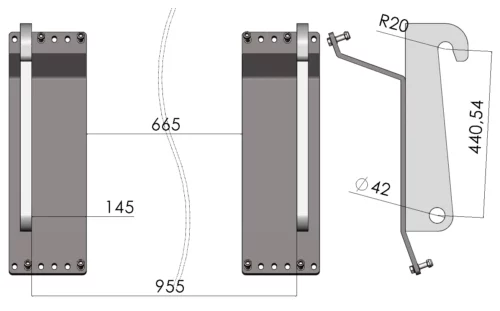

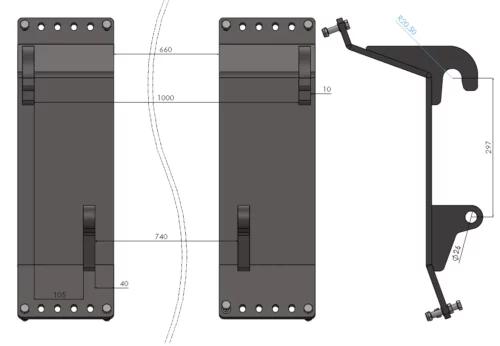

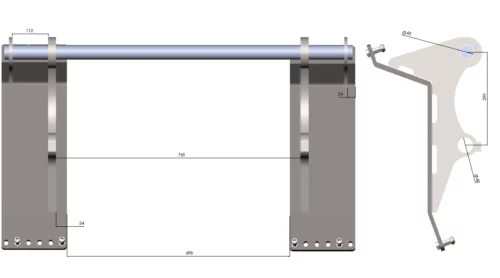

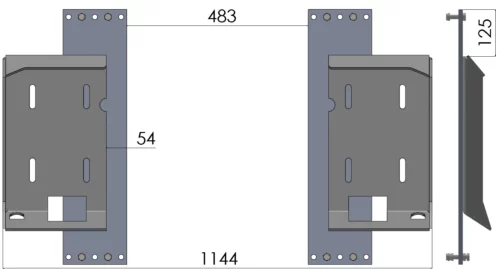

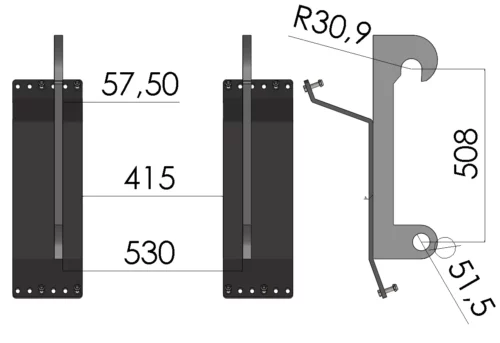

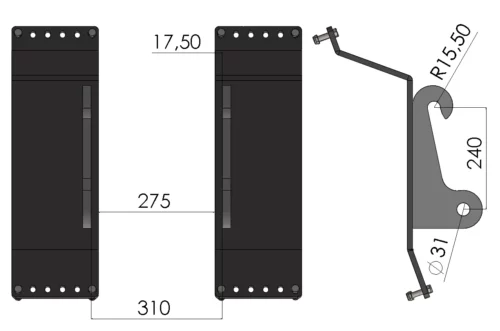

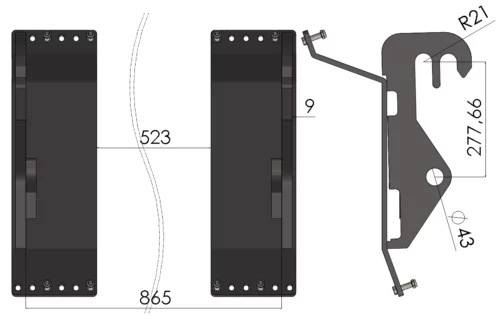

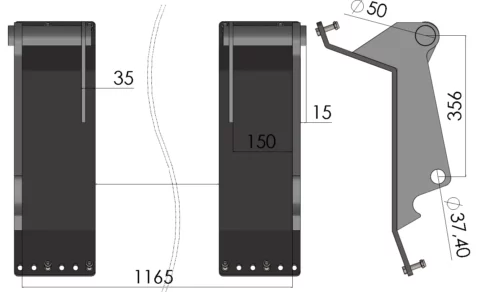

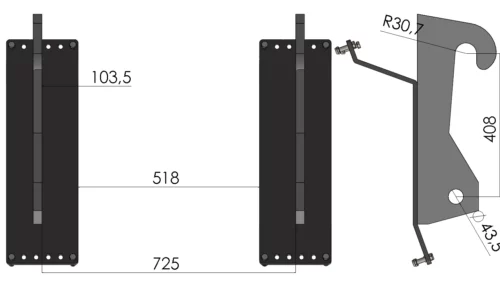

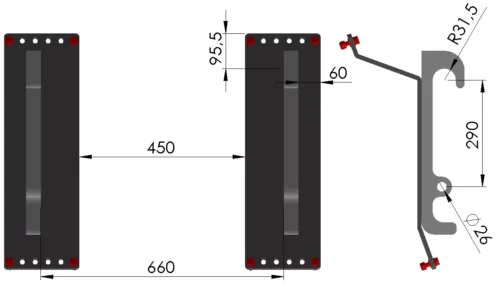

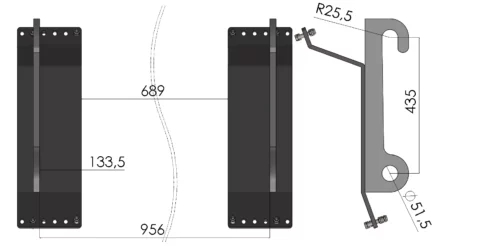

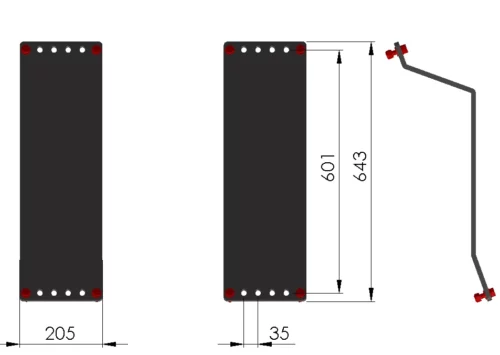

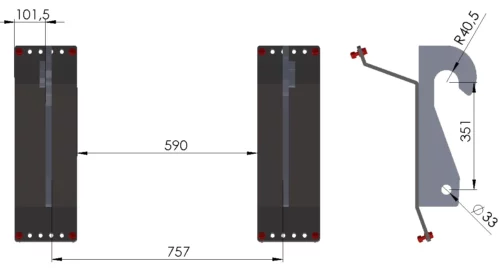

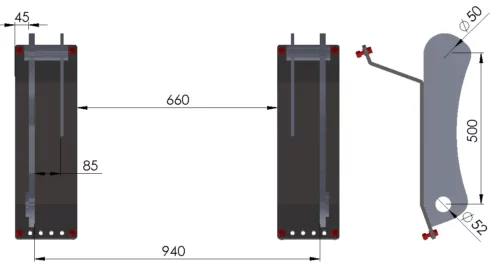

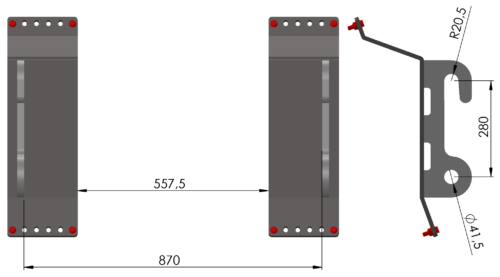

Mounting brackets

Wide variety of solutions for tractors, loaders and excavators

Hydraulic cutting angle control

Change cutting angle on the go

The hydraulic cutting angle control makes it possible to adjust the angle of the attachment tool via the vehicle's hydraulic control. The attached tool on the HXF 3302 Tele can be adjusted between -20° (vertical position) and 90° (horizontal position).

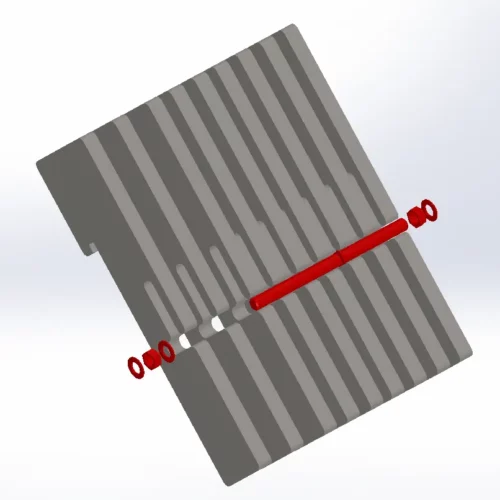

Automatic break-back system

Protects the machine from overloading when cutting large material

The break-back system consists of a mounted cylinder connected to an accumulator. The accumulator works by ensuring a soft return of the cylinder piston, so that no recoil effect occurs when the oil pressure in the cylinder is affected.

Equipment overview

| Hydraulic angle control incl. e-control of all functions* |

|

| Hydraulic switch from working to transport position |

|

| Automatic Hydraulic Break-back with pre-pressure |

|

| Oil flow divider |

|

| Anti-cavitation valve |

|

| Pressure relief valve |

|

| 1.5 m (5'2") hose kit for attachment tool |

|

| Euro brackets or universal plate |

|

| Counterweights, 101 kg (223 lb) |

|

| 8.5 m (27'11") hose kit (from front loader to tractor rear) - 3 pcs. |

|

| Other bracket types |

|

* When you buy the hydraulic angle control and the e-control with an oil flow divider, you only need one additional DA connection (and a zero-pressure tank drain where it is required).

Attachment tools

↕️ Range: 1.6 m (5'3")

🌳 Limb: Ø 12 cm (4.7")

↕️ Range: 2.0 m (6'7")

🌳 Limb: Ø 16 cm (6.3")

↕️ Range: 2.4 m (7'10")

🌳 Limb: Ø 21 cm (8.3")

↕️ Range: 1.3 m (4'3")

🌳 Limb: Ø 3 cm (1.2")

↕️ Range: 1.6 m (5'3")

🌳 Limb: Ø 4 cm (1.6")

↕️ Range: 1.7 m (5'7")

🌳 Limb: Ø 11 cm (4.3")

Models

HXF 3302 Tele (40 l/min), left handed, e-control

HXF 3302 Tele (40 l/min), right handed, e-control

HXF 3302 Tele (50 l/min), left handed, e-control

HXF 3302 Tele (50 l/min), right handed, e-control

Technical documents

Sales material

Related products

↔️ Arm: 1.3-1.9 m (4'2"-6'2")

⚙️ Tools: 2

↔️ Arm: 1.8 m (5'11")

⚙️ Tools: 6

↔️ Arm: 2.2 m (7'3")

⚙️ Tools: 7

↔️ Arm: 1.4-2.2 m (4'7"-7'3")

⚙️ Tools: 7

↔️ Arm: 2.5 m (8'2")

⚙️ Tools: 8

↔️ Arm: 1.6-2.5 m (5'3"-8'2")

⚙️ Tools: 8

↔️ Arm: 1.8 m (5'11")

⚙️ Tools: 6

↔️ Arm: 2.2 m (7'3")

⚙️ Tools: 11

↔️ Arm: 1.4-2.2 m (4'7"-7'3")

⚙️ Tools: 11

↔️ Arm: 2.5 m (8'2")

⚙️ Tools: 13

↔️ Arm: 1.6-2.5 m (5'3"-8'2")

⚙️ Tools: 13

FAQ

We sell our products through a network of dealers. We encourage you to contact your local GreenTec dealer for more information.

If you need any sales advice or cannot find a dealer near you, feel free to contact us on telephone: +45 75553644 or e-mail: sales@greentec.eu

We are available Monday to Thursday from 08.00 - 16.00 CET and Friday from 08.00 - 15.00 CET.

All products are manufactured in Denmark at our production facilities which consist of 5,500 m². We have employees welding components, assembling machines and checking features before the product is shipped to the customer.

We love to give customers a tour of our factory. If you are planning a visit to Denmark, you can schedule an appointment through e-mail: sales@greentec.eu

Our dealers sometimes do demonstrations. You must contact your local GreenTec dealer and ask if they have any upcoming demonstrations.

You cannot rent GreenTec machines directly through us.

We encourage you to contact your local GreenTec dealer to get a list of customers that might be able to offer this service.