1.3 m

Horizontal working width

< 7 cm

Maximum branch thickness

5 km/h

Maximum driving speed

2-years warranty

High quality materials that ensure a long life

Overview

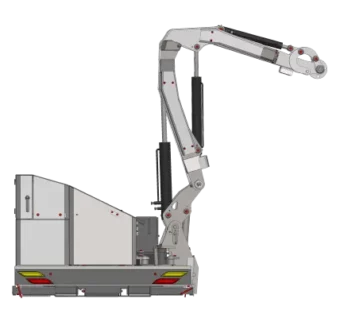

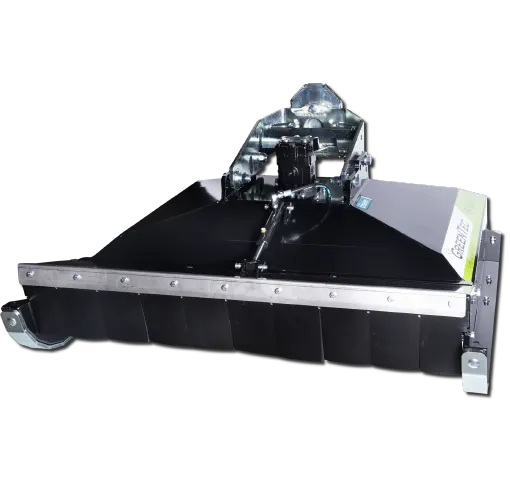

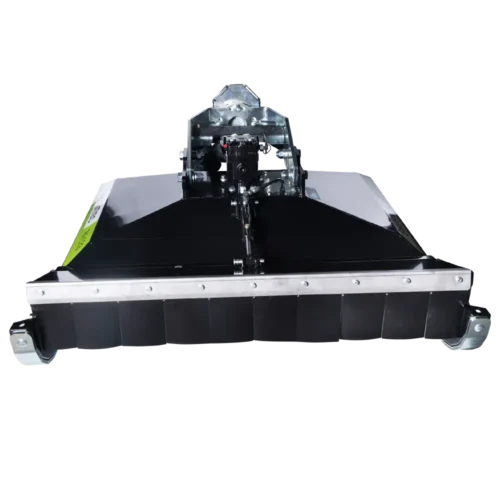

RX 133

The RX 133 is a hydraulic brush cutter specially developed for use in extreme conditions with stones and tree stumps. The brush cutter destroy any obstacle in its way. Whether that be branches, shrubs or the like.

The RX 133 can be mounted on large vehicles, such as tractors and excavators.

Powerful features

Grass, hedges, shrubs, tree stumps, etc.

Crushes and shreds branches

Long life and minimal maintenance

Quick jump to

Specifications

RX 133

| Working width |

1.3 m

|

4'3"

|

| Branch thickness |

7 cm

|

2.76”

|

| Driving speed up to |

5 km/h

|

3.11 mph

|

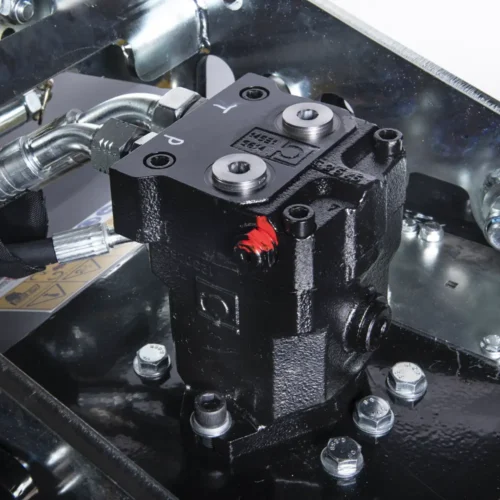

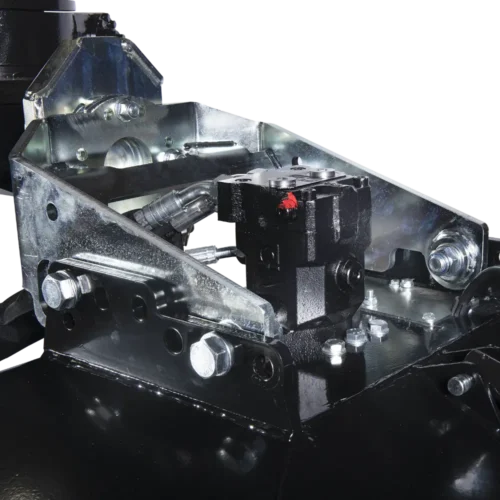

| Required hydraulic connections |

1 x double acting + 1 x drain

|

|

| Oil flow |

85-110 l/min @ 210-315 bar

|

22.5-29.1 gpm @ 3046-4569 psi

|

| Weight |

350 kg

|

772 lb

|

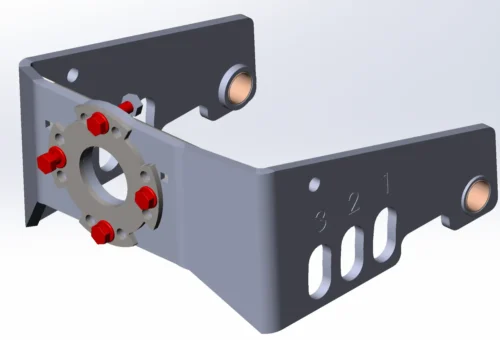

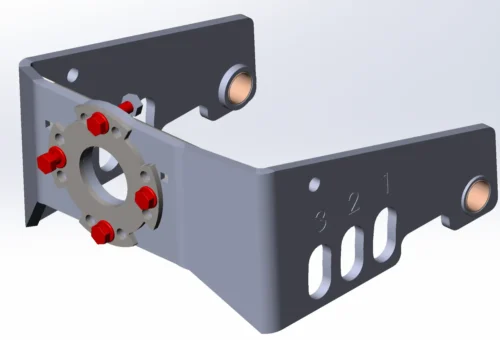

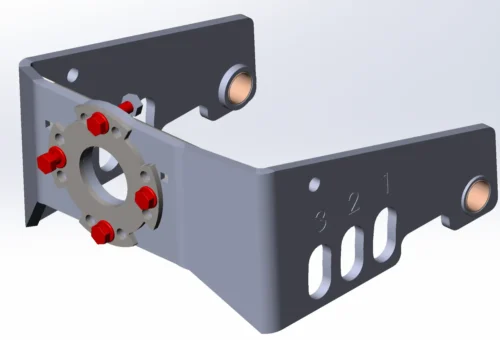

Under the hood

RX 133

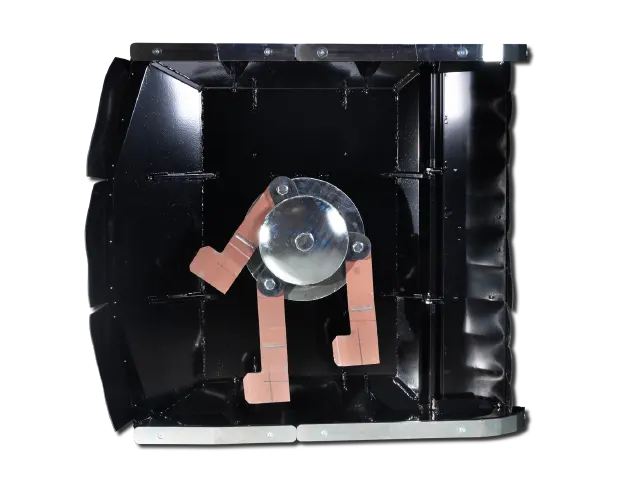

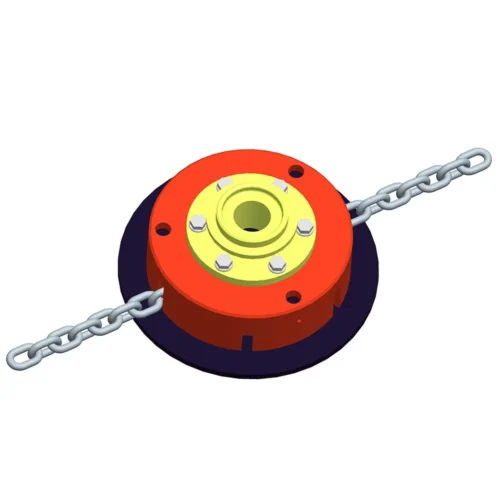

Continuous duty motor

Ensures high performance

Versatile cutting system

Chains or blades

Pressure-regulated front shield

Easier inflow of material

Strong build

Long life and minimal maintenance

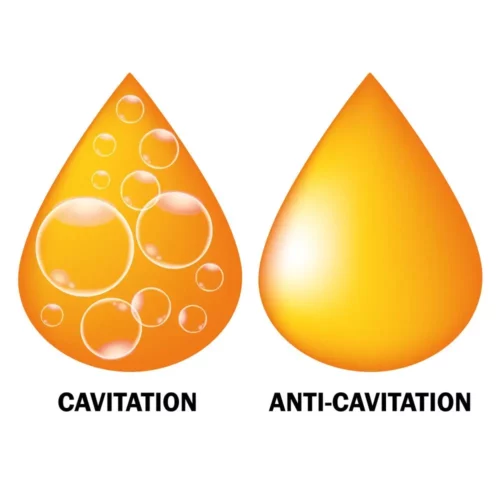

Anti-cavitation valve

Minimize the risk of cavitation damage in connection with insufficient inlet pressure

Rubber flap kit

Minimize flying materials during use

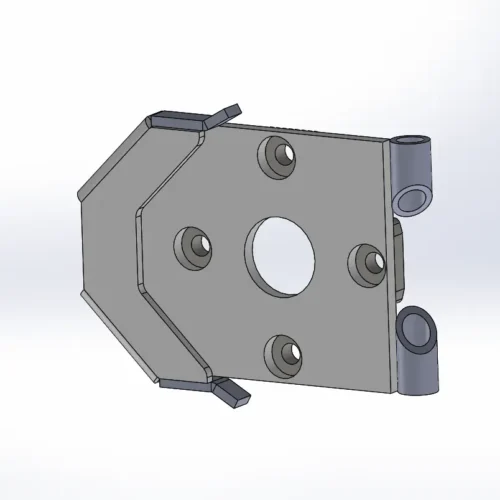

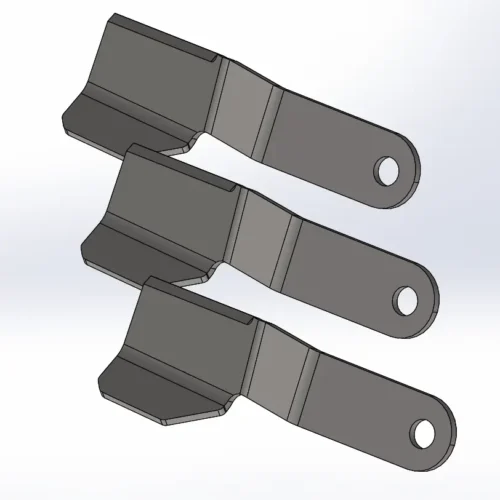

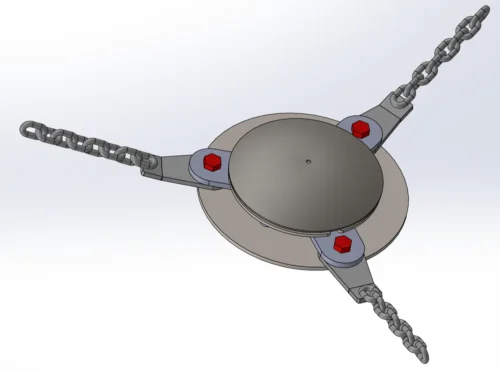

Versatile cutting system

Choose between chains or blades

The RX 133 comes with two cutting systems: chains or blades. The chains are used for mowing grass and shrubs in stony conditions. The blades are used for hedge cutting and grass mowing in normal conditions. Both systems are very robust.

Equipment overview

| Continuous duty motor |

|

| Anti-cavitation valve |

|

| Strenx 700 high strength steel |

|

| Reinforced construction |

|

| Pressure-regulated front shield |

|

| Optional HD blades or 13 mm (0.51") chains |

|

| Rubber flap kit |

|

| Adjustable floating suspension |

|

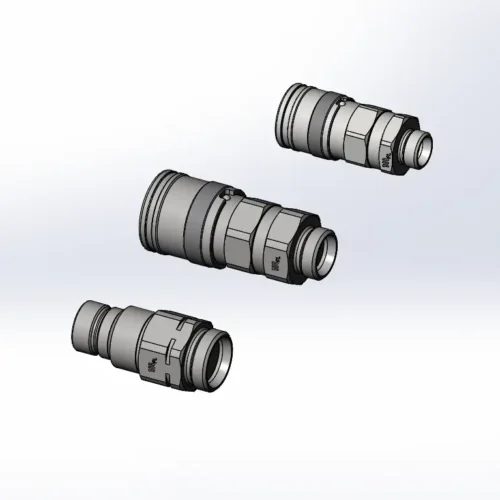

| Quick release, hydraulic |

|

| Quick release, mechanical |

|

| Chain magazine incl. chains |

|

Mounting options

↔️ Arm: 5.3 m (17'5")

↕️ Arm: 5.1 m (16'9")

↔️ Arm: 5.3 m (17'5")

↕️ Arm: 5.1 m (16'9")

↔️ Arm: 5.3 m (17'5")

↕️ Arm: 5.1 m (16'9")

↔️ Arm: 6.3 m (20'8")

↕️ Arm: 6.1 m (20')

↔️ Arm: 6.3 m (20'8")

↕️ Arm: 6.1 m (20')

↔️ Arm: 6.3 m (20'8")

↕️ Arm: 6.1 m (20')

↔️ Arm: 7.3 m (23'11")

↕️ Arm: 7.1 m (23'4")

↔️ Arm: 7.3 m (23'11")

↕️ Arm: 7.1 m (23'4")

↔️ Arm: 8.3 m (27'3")

↕️ Arm: 8.1 m (26'7")

↔️ Arm: 8.3 m (27'3")

↕️ Arm: 8.1 m (26'7")

↔️ Arm: 5.2 m (17'1")

↕️ Arm: 5.1 m (16'9")

↔️ Arm: 6.2 m (20'4")

↕️ Arm: 6.1 m (20')

↔️ Arm: 7.2 m (23'7")

↕️ Arm: 7.1 m (23'4")

↔️ Arm: 8.2 m (26'11")

↕️ Arm: 8.1 m (26'7")

Models

RX 133 (85-110 l/min), center

FAQ

We sell our products through a network of dealers. We encourage you to contact your local GreenTec dealer for more information.

If you need any sales advice or cannot find a dealer near you, feel free to contact us on telephone: +45 75553644 or e-mail: sales@greentec.eu

We are available Monday to Thursday from 08.00 - 16.00 CET and Friday from 08.00 - 15.00 CET.

All products are manufactured in Denmark at our production facilities which consist of 5,500 m². We have employees welding components, assembling machines and checking features before the product is shipped to the customer.

We love to give customers a tour of our factory. If you are planning a visit to Denmark, you can schedule an appointment through e-mail: sales@greentec.eu

Our dealers sometimes do demonstrations. You must contact your local GreenTec dealer and ask if they have any upcoming demonstrations.

You cannot rent GreenTec machines directly through us.

We encourage you to contact your local GreenTec dealer to get a list of customers that might be able to offer this service.