2.4 m

Vertical working width

< 21 cm

Maximum branch thickness

5 km/h

Maximum driving speed

2-years warranty

High quality materials that ensure a long life

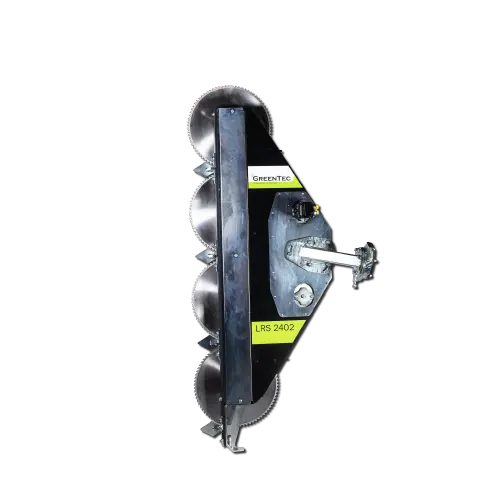

Overview

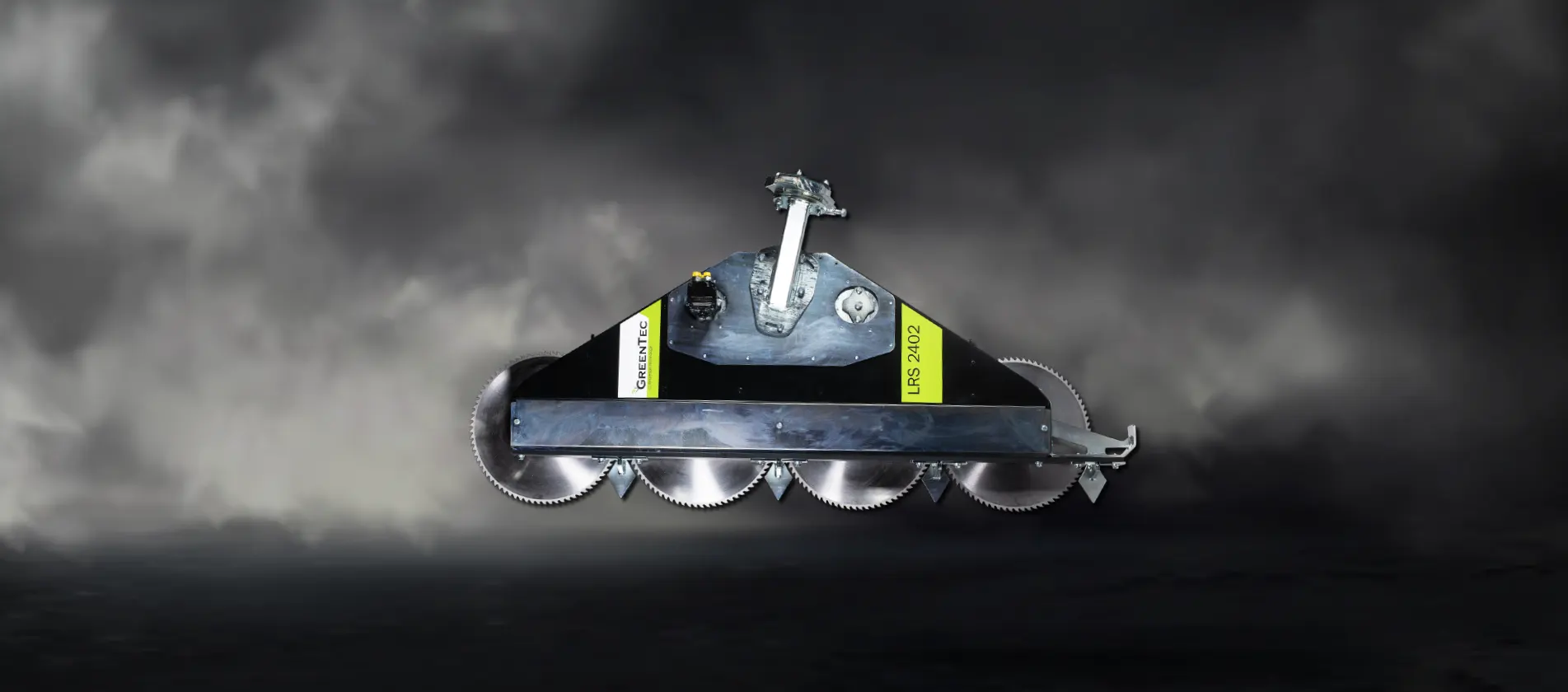

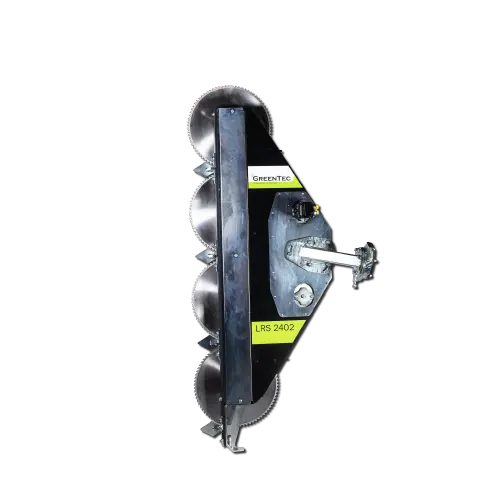

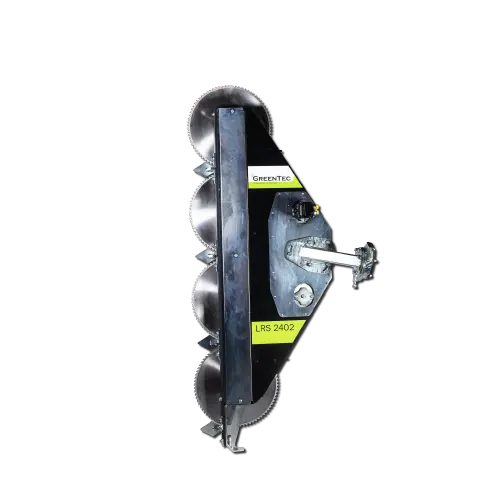

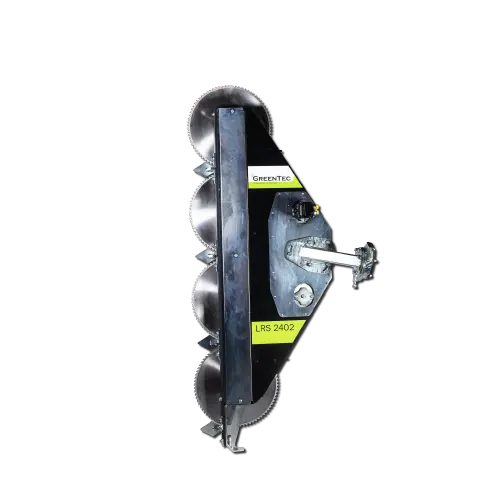

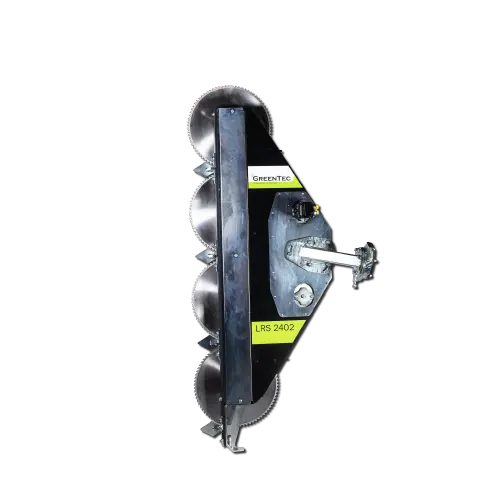

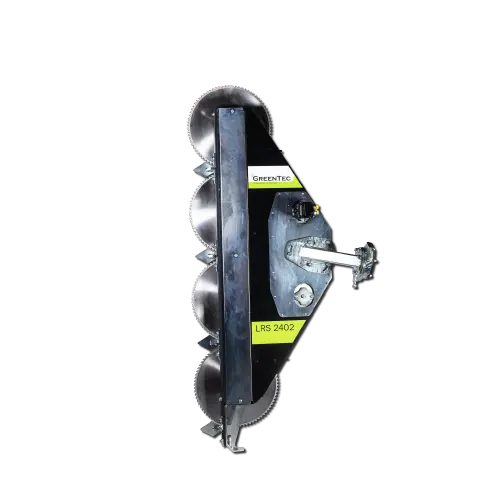

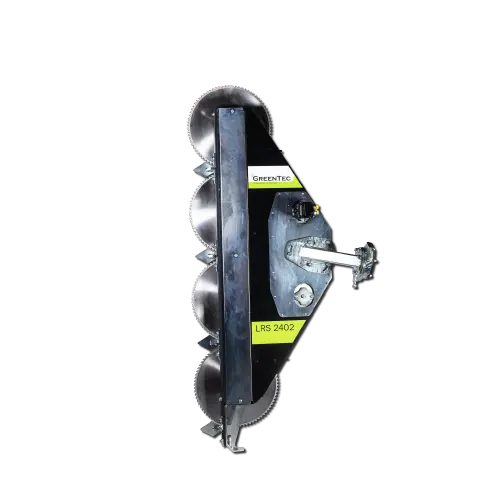

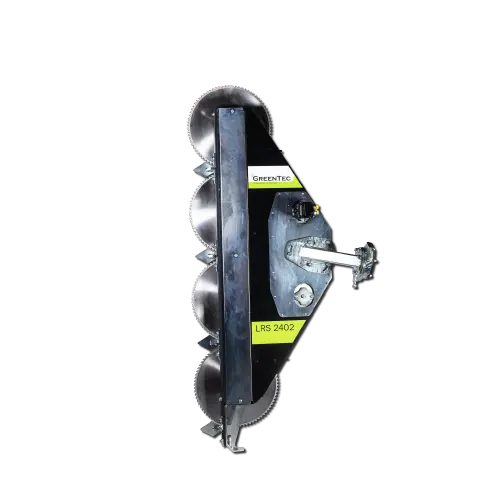

LRS 2402

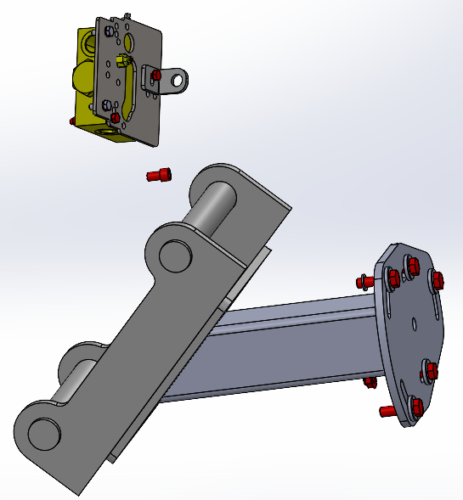

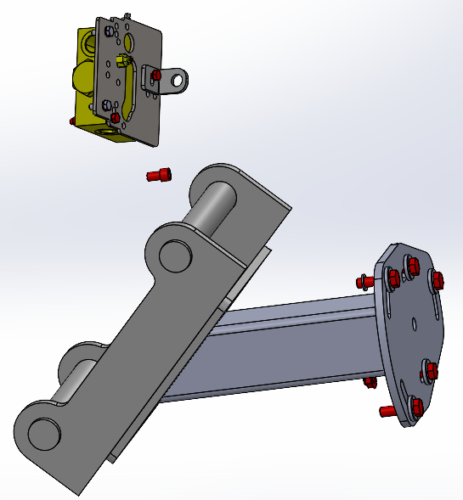

The Quadsaw LRS 2402 wields four circular blades with carbide tipped teeth that are extremely sharp and provide a smooth cut of branches and limbs up to 21 cm (8.27”) in thickness. The circular saw has many uses, such as trimming back hedgerows or maintaining paths and roads in forest areas.

The saw is hydraulic driven and can be mounted on large and medium-sized vehicles, such as telehandlers, front-end loaders, tractors and excavators.

Powerful features

Smooth cut of thick and thin branches

High efficiency and low power requirement

Long life and minimal maintenance

Quick jump to

Specifications

LRS 2402

| Working width |

2.4 m

|

7’10”

|

| Saw blades with Widia teeth |

4 pcs: Ø 59.5 cm

|

4 pcs: Ø 1’11"

|

| Branch thickness |

0.5-21 cm

|

0.20”-8.27”

|

| Driving speed up to |

5 km/h

|

3.11 mph

|

| Blade speed |

3000-3200 rpm

|

|

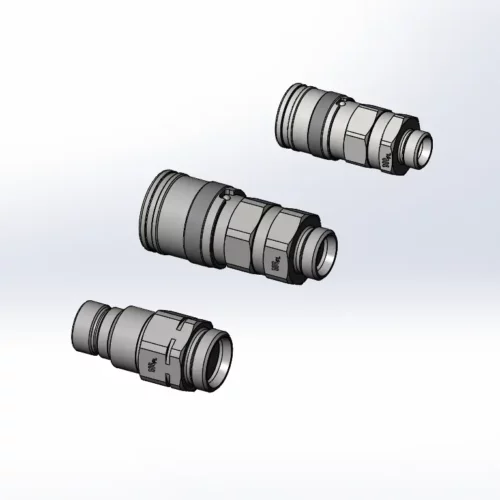

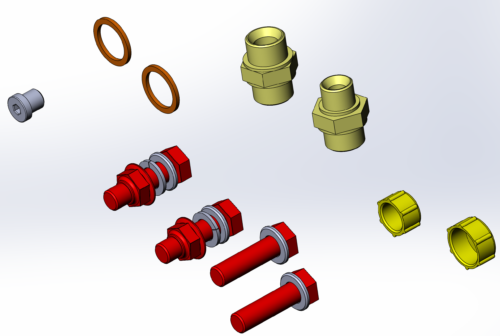

| Required hydraulic connections |

1 x double acting + 1 x drain

|

|

| Minimum oil flow, 28 ccm motor |

85 l/min @ 150 bar

|

22.5 gpm @ 2176 psi

|

| Alternative oil flow, 19 ccm motor |

50 l/min @ 180 bar

|

13.2 gpm @ 2611 psi

|

| Weight |

239 kg

|

527 lb

|

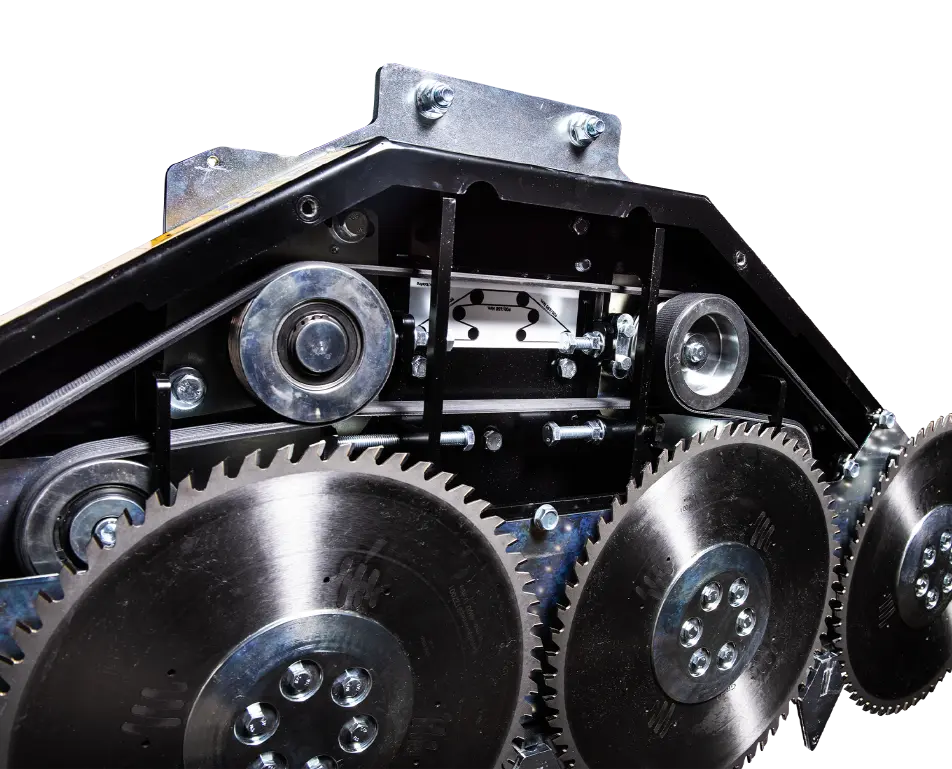

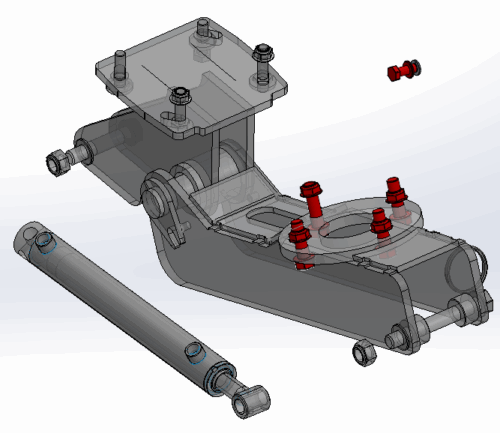

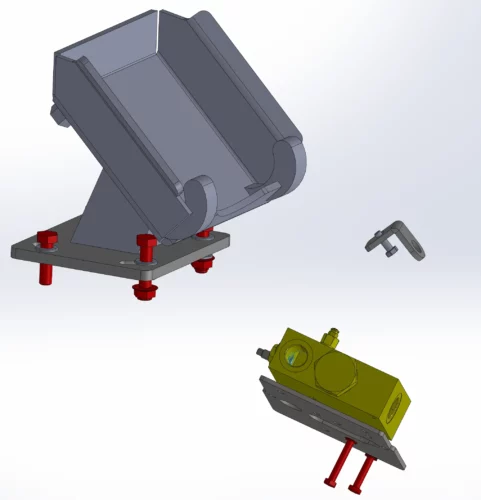

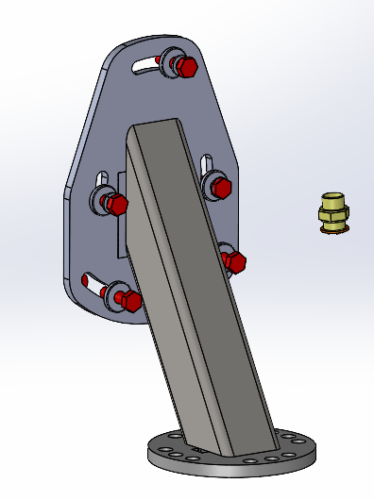

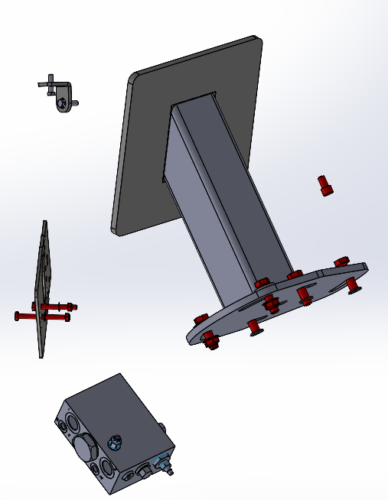

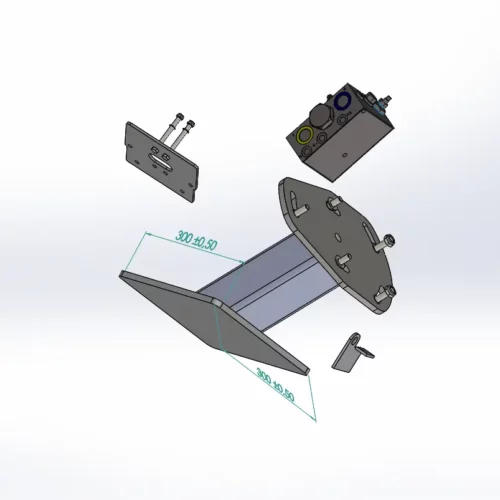

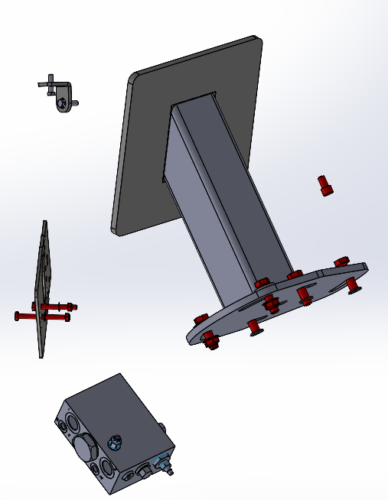

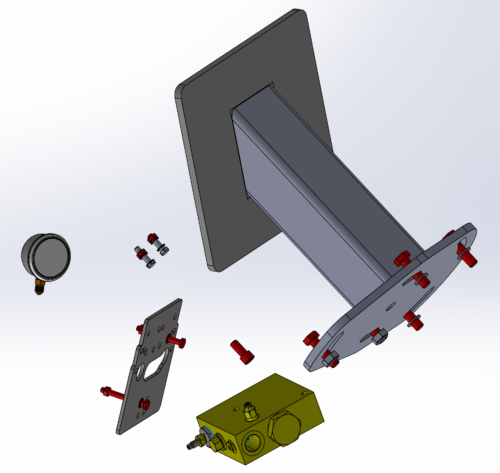

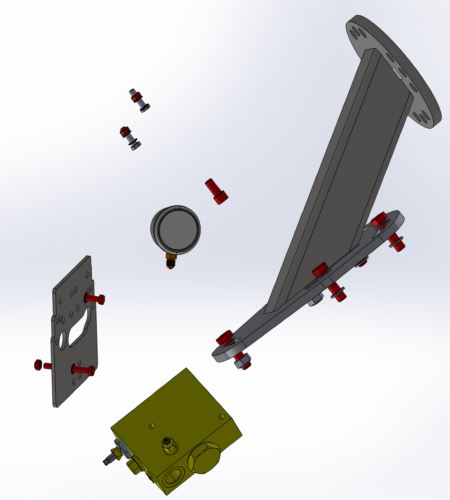

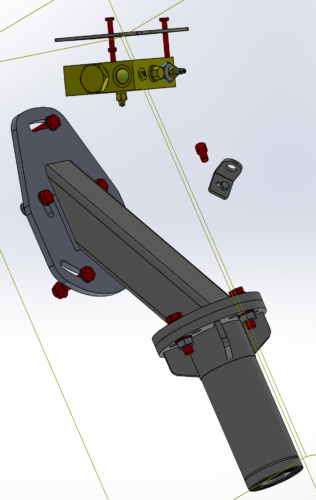

Under the hood

LRS 2402

Widia carbide tipped teeth

Smooth cut and long life

Power band belt drive

Maximum power transfer

Branch guider

Provides an even intake of branches

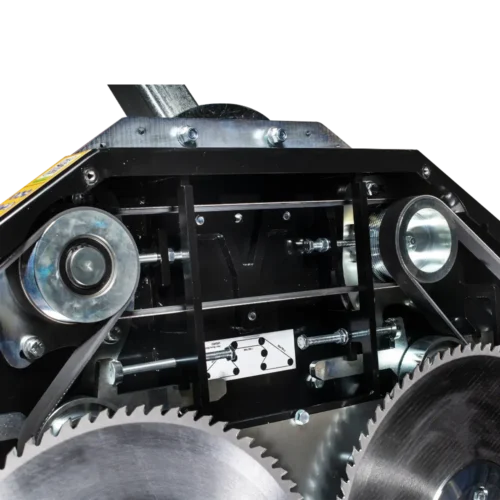

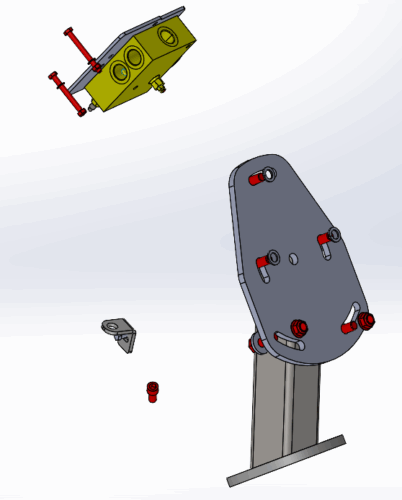

Accessibility

Easy to access the belt drive for maintenance

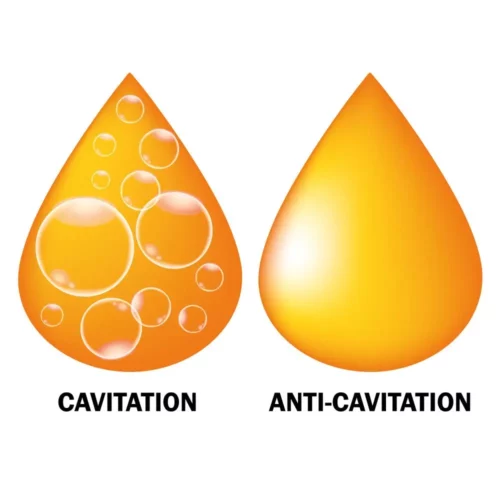

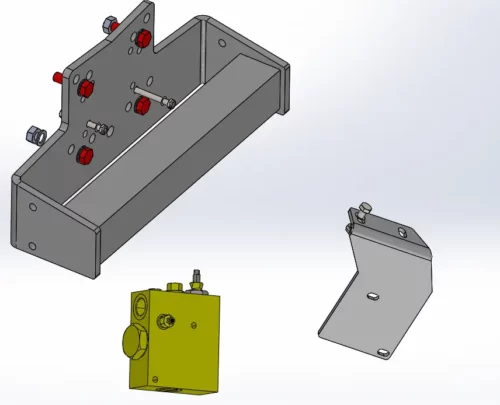

Anti-cavitation valve

Minimize the risk of cavitation damage in connection with insufficient inlet pressure

Smart design

The blades overlap each other

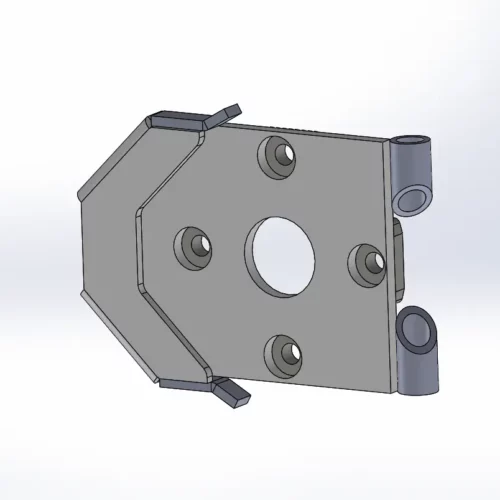

Blade holder

Stabilizes the blade and ensures strength

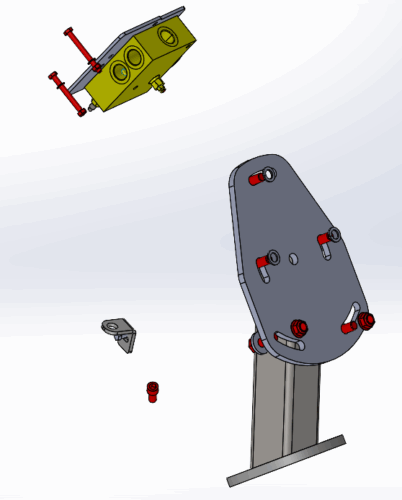

Right and left versions

Possibility of rebuilding the saw for working right or left handed by moving components

High quality saw blades

Prune branches with a smooth cut and reduce diseases to trees

The sharp carbide tipped saw teeth enable trees to heal wounds faster so the risk of being affected by diseases and infections are reduced significantly.

The saw blades are long-lasting and can be used for 100 hours before sharpening is required. After sharpening, they can last another 100 hours.

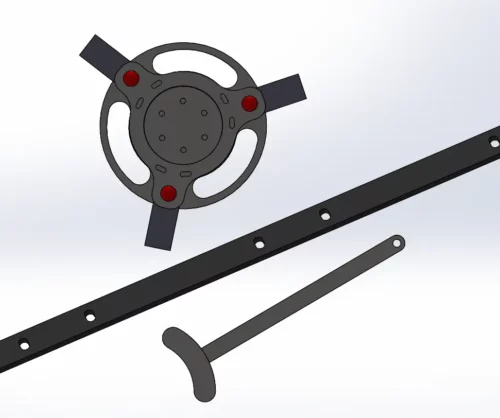

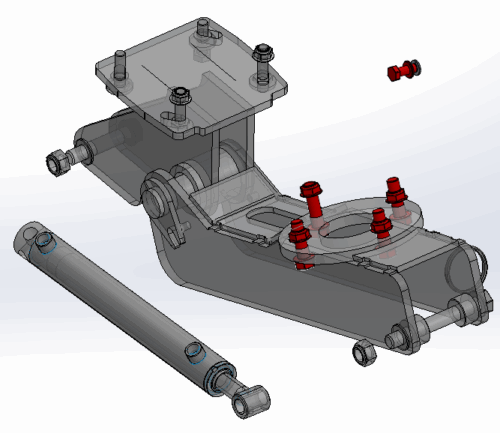

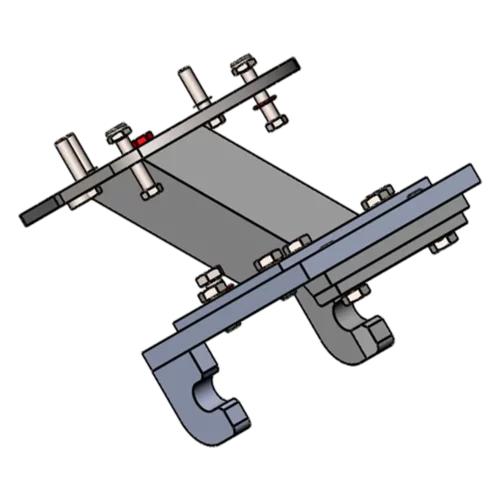

Power Band belt drive

Achieve a high efficiency while keeping a low power requirement

The transmission system is fitted with a wide Power Band belt with six tracks which enhances the performance as more force is generated. The large circumference on the pulley provides better grip and helps with transferring a high amount of torque.

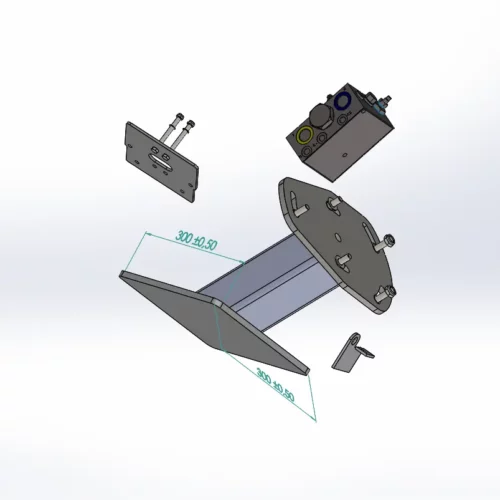

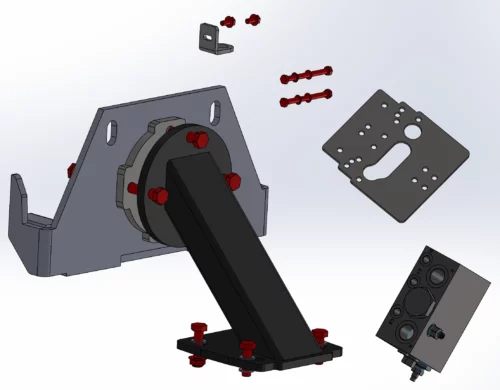

Equipment overview

| Blade diameter: 59.5 cm (1’11") |

|

| Continuous duty motor |

|

| Carbide tipped blades |

|

| Belt stretcher |

|

| Power Band belt drive |

|

| Belt tension gauge |

|

| Anti-cavitation valve |

|

| Large smooth surface |

|

| Narrow body |

|

| Branch guider at each saw blade |

|

| 4 circular blades in a line |

|

| 7° angle allows overlap between the blades |

|

| Skid shoe (the saw avoids hitting the ground) |

|

| Pressure relief valve |

|

| Saw blades or rotor blades, 4 pieces |

|

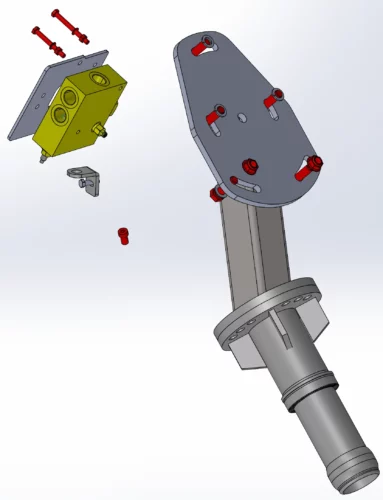

| Quick release, hydraulic |

|

| Quick release, mechanical |

|

| Rotor blades, 4 pieces, retrofitted |

|

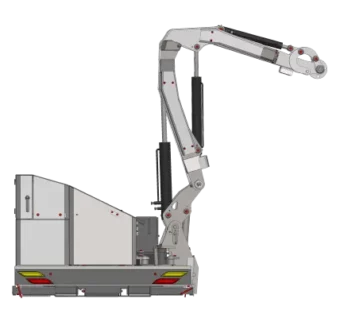

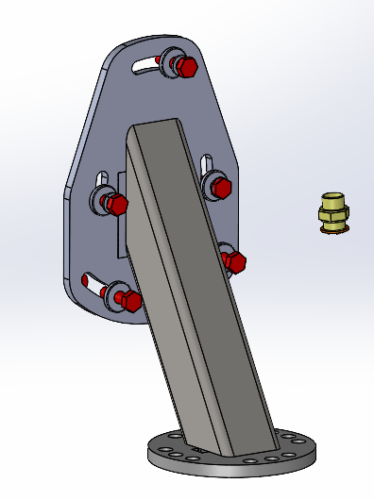

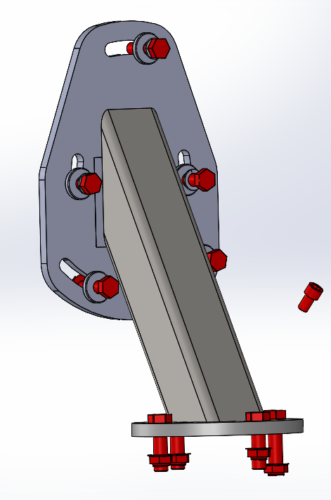

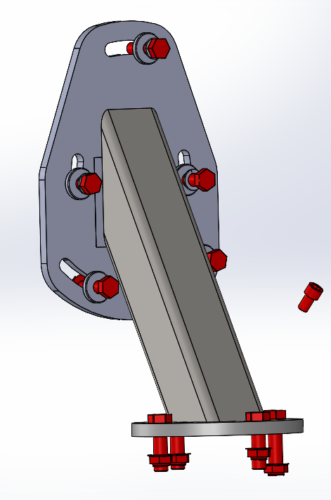

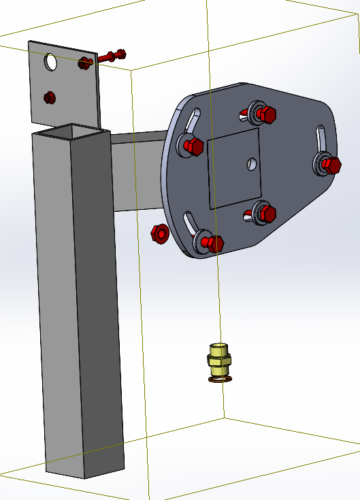

Mounting options

↔️ Arm: 2.5 m (8'2")

⚙️ Tools: 8

↔️ Arm: 1.6-2.5 m (5'3"-8'2")

⚙️ Tools: 8

↔️ Arm: 5.3 m (17'5")

↕️ Arm: 5.1 m (16'9")

↔️ Arm: 5.3 m (17'5")

↕️ Arm: 5.1 m (16'9")

↔️ Arm: 5.3 m (17'5")

↕️ Arm: 5.1 m (16'9")

↔️ Arm: 6.3 m (20'8")

↕️ Arm: 6.1 m (20')

↔️ Arm: 6.3 m (20'8")

↕️ Arm: 6.1 m (20')

↔️ Arm: 6.3 m (20'8")

↕️ Arm: 6.1 m (20')

↔️ Arm: 7.3 m (23'11")

↕️ Arm: 7.1 m (23'4")

↔️ Arm: 7.3 m (23'11")

↕️ Arm: 7.1 m (23'4")

↔️ Arm: 8.3 m (27'3")

↕️ Arm: 8.1 m (26'7")

↔️ Arm: 8.3 m (27'3")

↕️ Arm: 8.1 m (26'7")

↔️ Arm: 5.2 m (17'1")

↕️ Arm: 5.1 m (16'9")

↔️ Arm: 6.2 m (20'4")

↕️ Arm: 6.1 m (20')

↔️ Arm: 7.2 m (23'7")

↕️ Arm: 7.1 m (23'4")

↔️ Arm: 8.2 m (26'11")

↕️ Arm: 8.1 m (26'7")

Models

LRS 2402 (50 l/min), left handed, without drain

LRS 2402 (50 l/min), left handed, anti-cavitation valve

LRS 2402 (50 l/min), left handed, anti-cavitation valve, oil flow divider

LRS 2402 (85 l/min), left handed, anti-cavitation valve

LRS 2402 (85 l/min), left handed, anti-cavitation valve, oil flow divider

LRS 2402 (50 l/min), right handed, without drain

LRS 2402 (50 l/min), right handed, anti-cavitation valve

LRS 2402 (50 l/min), right handed, anti-cavitation valve, oil flow divider

LRS 2402 (85 l/min), right handed, anti-cavitation valve

LRS 2402 (85 l/min), right handed, anti-cavitation valve, oil flow divider

Technical documents

Name

File type

Related products

↕️ Range: 1.4 m (4'7")

🌳 Limb: Ø 10 cm (3.9")

↕️ Range: 1.6 m (5'3")

🌳 Limb: Ø 12 cm (4.7")

↕️ Range: 2.0 m (6'7")

🌳 Limb: Ø 16 cm (6.3")

↕️ Range: 1.7 m (5'7")

🌳 Limb: Ø 11 cm (4.3")

↕️ Range: 2.3 m (7'7")

🌳 Limb: Ø 11 cm (4.3")

↕️ Range: 2.7 m (8'10")

🌳 Limb: Ø 11 cm (4.3")

↕️ Range: 1.7 m (5'7")

🌳 Limb: Ø 6 cm (2.4")

↕️ Range: 2.1 m (6'11")

🌳 Limb: Ø 6 cm (2.4")

↕️ Range: 2.4 m (7'10")

🌳 Limb: Ø 6 cm (2.4")

FAQ

We sell our products through a network of dealers. We encourage you to contact your local GreenTec dealer for more information.

If you need any sales advice or cannot find a dealer near you, feel free to contact us on telephone: +45 75553644 or e-mail: sales@greentec.eu

We are available Monday to Thursday from 08.00 - 16.00 CET and Friday from 08.00 - 15.00 CET.

All products are manufactured in Denmark at our production facilities which consist of 5,500 m². We have employees welding components, assembling machines and checking features before the product is shipped to the customer.

We love to give customers a tour of our factory. If you are planning a visit to Denmark, you can schedule an appointment through e-mail: sales@greentec.eu

Our dealers sometimes do demonstrations. You must contact your local GreenTec dealer and ask if they have any upcoming demonstrations.

You cannot rent GreenTec machines directly through us.

We encourage you to contact your local GreenTec dealer to get a list of customers that might be able to offer this service.