19 tools

Grass, hedge and tree maintenance

5.3 m

Huge flexibility with the arm reach

5,000 kg

Minimum vehicle weight

2-years warranty

High quality materials that ensure a long life

Overview

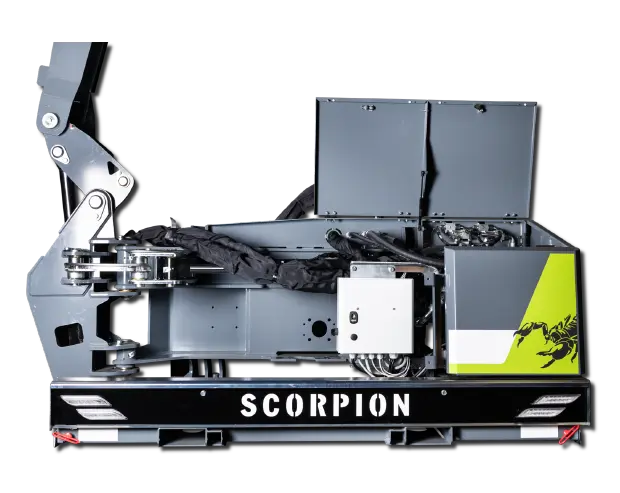

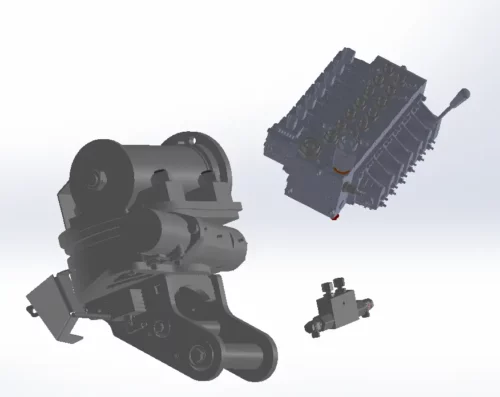

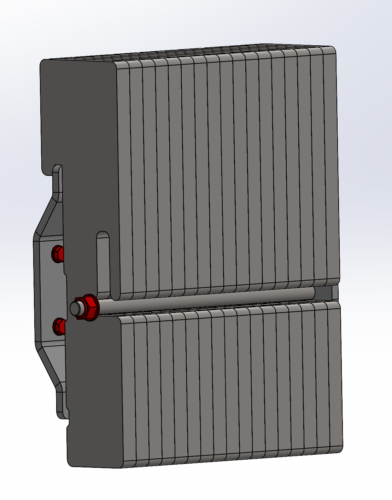

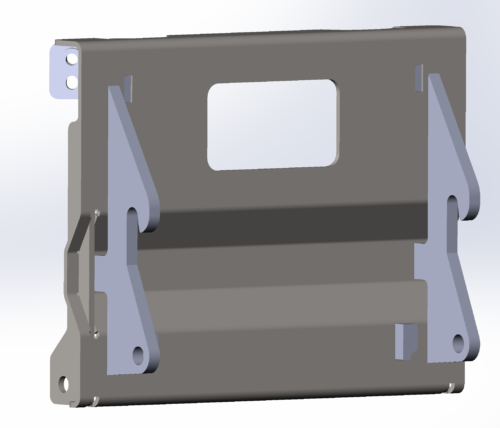

Scorpion 530 S - Basic Front

Our Scorpion 530 S - Basic Front is a professional boom mower used by municipalities, agricultural contractors, forest workers and landscapers. A large selection of tools can be attached to the Scorpion boom mower for roadside maintenance, hedge cutting and tree trimming. The wide range of attachment tools make the Scorpion 530 S - Basic Front a popular choice throughout the entire year.

The Scorpion 530 S - Basic Front boom mower is designed for medium-sized tractors and loaders with a weight of at least 5,000 kg (8,819 lb). Instead of the traditional three-point mounting, the Scorpion models have four mounting points on the mainframe. It is a much faster and reliable mounting system.

Powerful features

Control the arm with or without parallel motion

Made of Strenx 700 high-strength steel

Hydraulic turn of the arm with Power Control

Quick jump to

Specifications

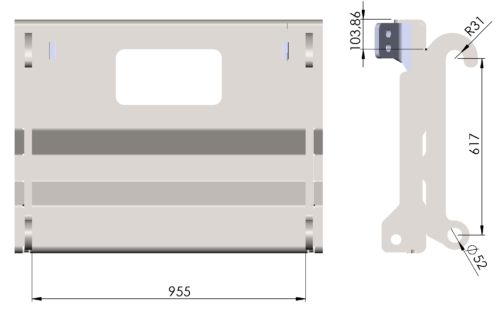

Scorpion 530 S - Basic Front

| Horizontal reach |

5.3 m

|

17'5"

|

| Vertical reach |

5.1 m

|

16'9"

|

| Transport width |

2.2 m

|

7'3"

|

| Hydraulic system |

115 l/min @ 230 bar

|

30.38 gpm @ 3336 psi

|

| Weight without tools |

985 kg

|

2,172 lb

|

| Minimum size of tractor |

5,000 kg

|

11,023 lb

|

Under the hood

Scorpion 530 S - Basic Front

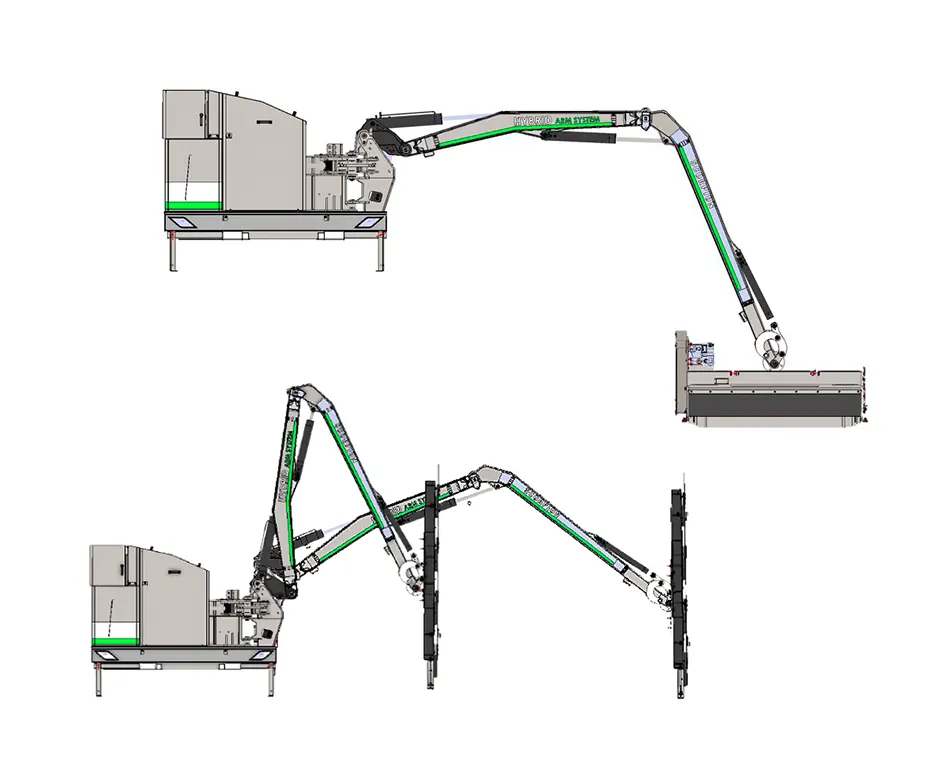

Hybrid arm system

Control the arm with or without parallel motion

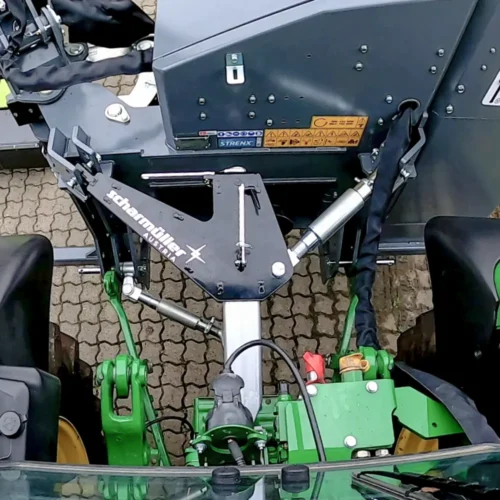

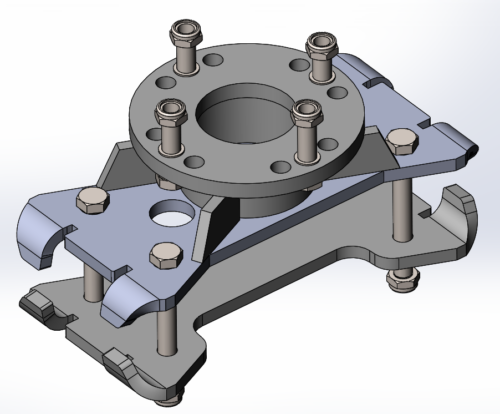

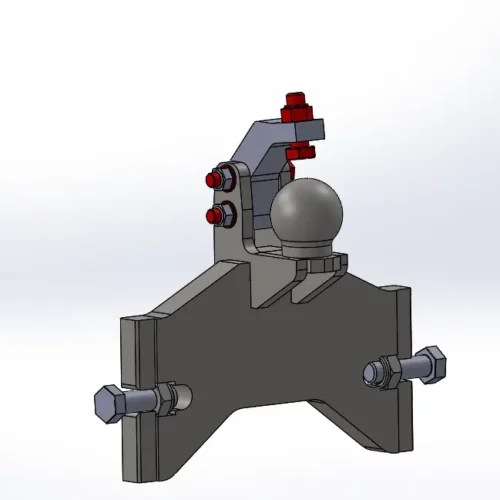

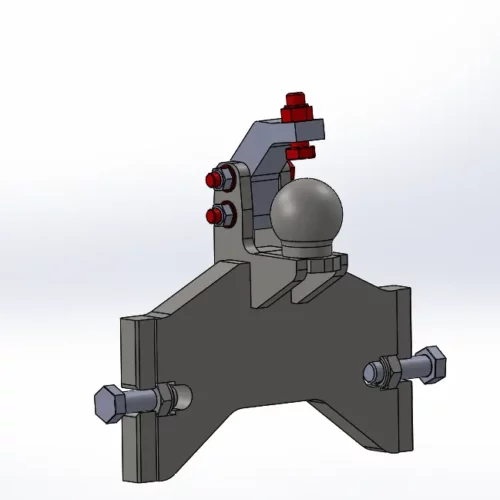

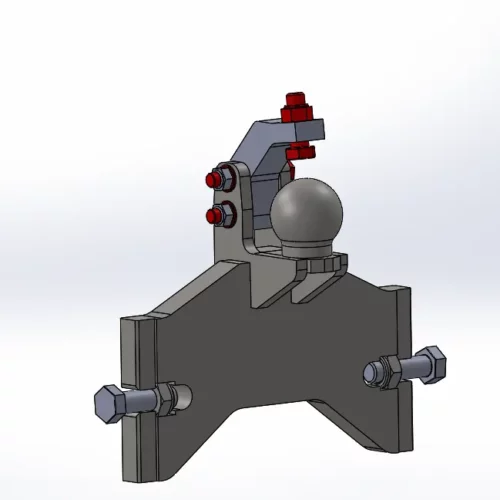

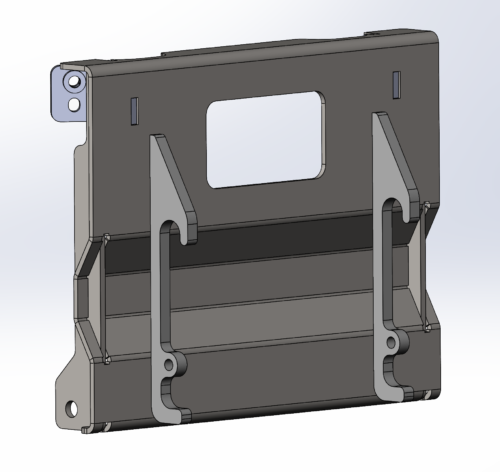

4-point mounting

Easy installation that provides 100% stability

Danfoss joystick

4 proportional functions

Air stream control

Effective oil cooling

LED lights

Visible from a long distance

Flexibility

155° hydraulic turn of the arm

Strenx 700 steel

One of the most durable steel types in the world

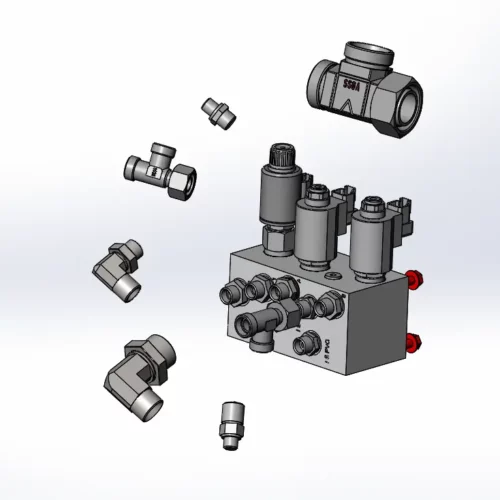

Hydraulic system

Oil supply from vehicle

Rotor Flex (optional)

With Rotor Flex the cutting head is always in the driver’s natural field of vision

Rotor Flex has a double pivot joint which enables you to move the cutting head forward, so it is in the driver’s natural field of vision. The cutting head can also be moved behind the vehicle which is useful for verge mowing on small roads with oncoming traffic.

Auto Height Control (optional)

Relieves the driver from manual adjusting to the contours of the terrain

Auto Height Control is used for verge and ditch mowing. It ensures that the cutting head floats above the surface and does not mow into the ground by following the contours of the terrain. This is all done automatically. The driver does not need to maneuver the boom mower with the joystick.

Hybrid arm system

Switch between parallel and non-parallel motion

The parallel motion takes place through a Master Slave System and is especially used for hedge trimming. The non-parallel motion shines in cramped conditions, such as forest roads and trails. It can also be particularly useful for grass mowing in slopes and ditches.

Equipment overview

| Hybrid Arm System with dual function |

|

| Strenx 700 steel construction |

|

| 155° hydraulic turn of the arm with power control |

|

| Danfoss proportional valve PVG 32/16 |

|

| Danfoss joystick with 4 proportional functions |

|

| 2 oil flows: 85 and 50 l/min (22.45 and 13.21 gpm) for attachment tool |

|

| Hydraulic float of arm and cutting angle |

|

| Oil cooler |

|

| Air Stream Control (effective oil cooling) |

|

| 4-point mounting for cat. 2 or 3 |

|

| Automatic Hydraulic Security (AHS) |

|

| Transport safety |

|

| LED lights |

|

| Auto Height Control (for verge mowing)* |

|

| Rotor Flex, double pivot joint (270° turn of cutting head and 180° cutting angle)* |

|

| Auto Flex, automatic vertical positioning* |

|

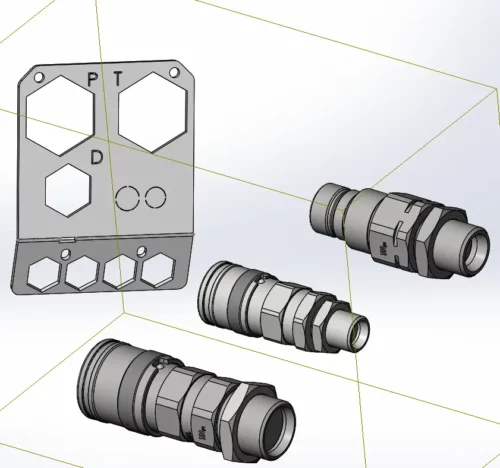

| Quick release, hydraulic |

|

| Quick release, mechanical |

|

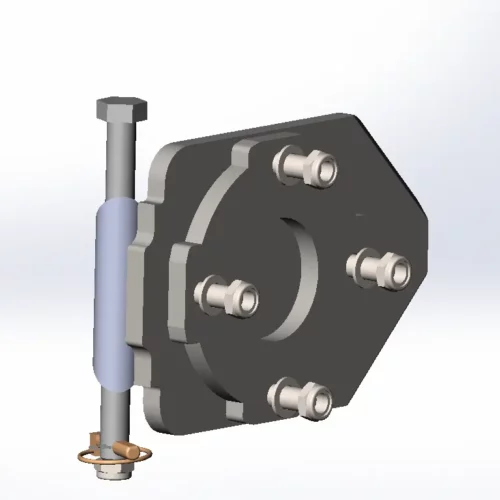

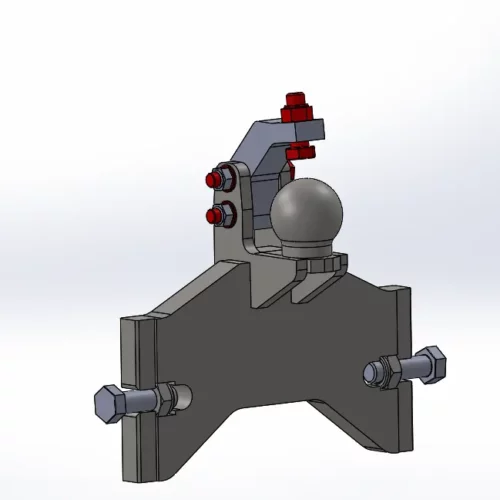

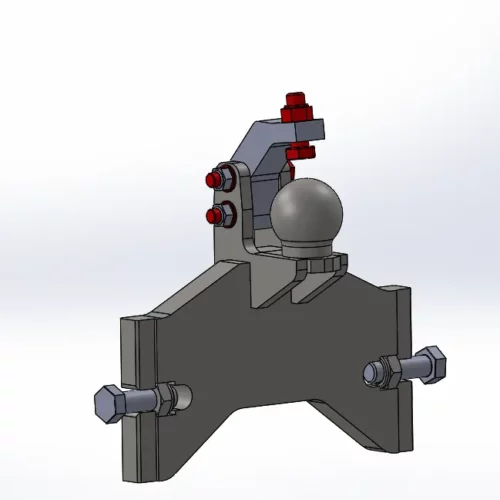

| K80 ball hitch for 4-point mounting** |

|

| 4-point frame for loaders |

|

| Brackets for loaders |

|

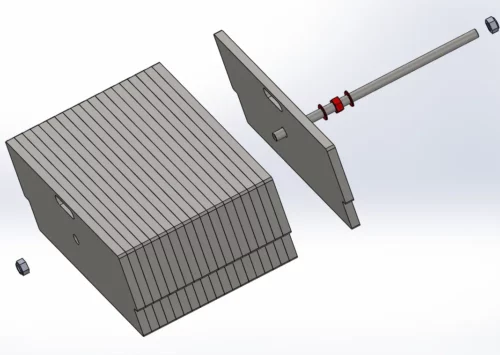

| 430 kg (948 lb) counterweights |

|

| 212 kg (467 lb) counterweights, additional |

|

* Cannot be retrofitted

** Requires K80 on the tractor at top bar height

Attachment tools

↕️ Range: 2.3 m (7'7")

🌳 Limb: Ø 4 cm (1.6")

↕️ Range: 1.6 m (5'3")

🌳 Limb: Ø 4 cm (1.6")

↕️ Range: 2.0 m (6'7")

🌳 Limb: Ø 16 cm (6.3")

↕️ Range: 2.4 m (7'10")

🌳 Limb: Ø 21 cm (8.3")

↕️ Range: 2.1 m (6'11")

🌳 Limb: Ø 6 cm (2.4")

↕️ Range: 2.4 m (7'10")

🌳 Limb: Ø 6 cm (2.4")

Models

Scorpion 530-6 S, Basic Front, right

Scorpion 530-6 S, Basic Front, left

Technical documents

Related products

↔️ Arm: 5.2 m (17'1")

↕️ Arm: 5.1 m (16'9")

↔️ Arm: 6.2 m (20'4")

↕️ Arm: 6.1 m (20')

↔️ Arm: 7.2 m (23'7")

↕️ Arm: 7.1 m (23'4")

↔️ Arm: 8.2 m (26'11")

↕️ Arm: 8.1 m (26'7")

↔️ Arm: 3.3 m (10'10")

↕️ Arm: 3.1 m (10'2")

↔️ Arm: 3.3 m (10'10")

↕️ Arm: 3.1 m (10'2")

↔️ Arm: 3.3 m (10'10")

↕️ Arm: 3.1 m (10'2")

↔️ Arm: 3.3 m (10'10")

↕️ Arm: 3.1 m (10'2")

↔️ Arm: 4.3 m (14'1")

↕️ Arm: 4.1 m (13'5")

↔️ Arm: 4.3 m (14'1")

↕️ Arm: 4.1 m (13'5")

↔️ Arm: 4.3 m (14'1")

↕️ Arm: 4.1 m (13'5")

↔️ Arm: 4.3 m (14'1")

↕️ Arm: 4.1 m (13'5")

↔️ Arm: 4.9 m (16'07")

↕️ Arm: 4.8 m (15'74")

↔️ Arm: 5.3 m (17'5")

↕️ Arm: 5.1 m (16'9")

↔️ Arm: 5.3 m (17'5")

↕️ Arm: 5.1 m (16'9")

↔️ Arm: 5.3 m (17'5")

↕️ Arm: 5.1 m (16'9")

↔️ Arm: 6.3 m (20'8")

↕️ Arm: 6.1 m (20')

↔️ Arm: 6.3 m (20'8")

↕️ Arm: 6.1 m (20')

↔️ Arm: 6.3 m (20'8")

↕️ Arm: 6.1 m (20')

↔️ Arm: 7.3 m (23'11")

↕️ Arm: 7.1 m (23'4")

↔️ Arm: 7.3 m (23'11")

↕️ Arm: 7.1 m (23'4")

↔️ Arm: 8.3 m (27'3")

↕️ Arm: 8.1 m (26'7")

↔️ Arm: 8.3 m (27'3")

↕️ Arm: 8.1 m (26'7")

FAQ

We sell our products through a network of dealers. We encourage you to contact your local GreenTec dealer for more information.

If you need any sales advice or cannot find a dealer near you, feel free to contact us on telephone: +45 75553644 or e-mail: sales@greentec.eu

We are available Monday to Thursday from 08.00 - 16.00 CET and Friday from 08.00 - 15.00 CET.

All products are manufactured in Denmark at our production facilities which consist of 5,500 m². We have employees welding components, assembling machines and checking features before the product is shipped to the customer.

We love to give customers a tour of our factory. If you are planning a visit to Denmark, you can schedule an appointment through e-mail: sales@greentec.eu

Our dealers sometimes do demonstrations. You must contact your local GreenTec dealer and ask if they have any upcoming demonstrations.

You cannot rent GreenTec machines directly through us.

We encourage you to contact your local GreenTec dealer to get a list of customers that might be able to offer this service.