1.0 m

Vertical working width

< 2 cm

Maximum branch thickness

2.5 km/h

Maximum vehicle driving speed

2-years warranty

High quality materials that ensure a long life

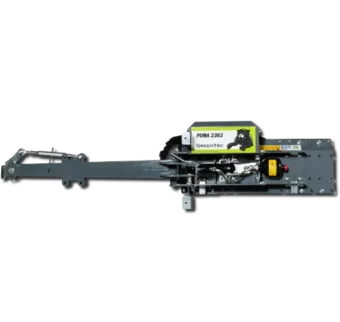

Overview

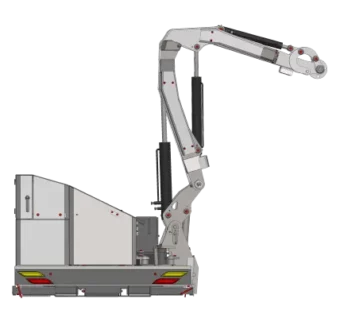

RC 102

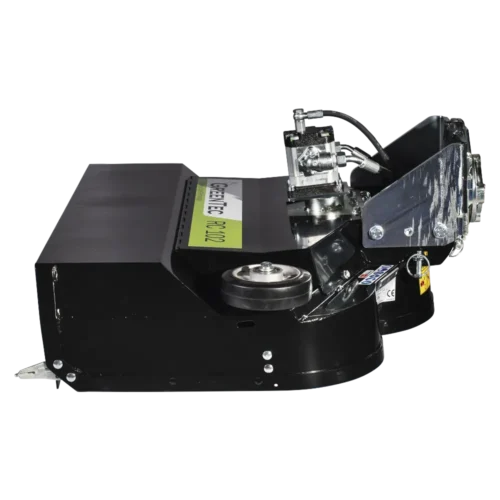

Save time and resources with our Rotary Hedge Cutter RC 102 which cuts and shreds hedges and bushes in the same workflow. The hedge debris can be left on the ground for decay as it is crushed into a thousand small pieces.

The hydraulic hedge trimmer attachment can be mounted on tractors, loaders and excavators. It is used by landscape gardeners, agricultural contractors and municipalities.

Powerful features

Reduce diseases in the hedges

Cut and pulverize branches simultaneously

Ideal solution for hedge maintenance in residential areas

Quick jump to

Specifications

RC 102

| Working width |

1.0 m

|

3'3"

|

| Number of rotors |

3 pieces

|

|

| Blades per rotor |

6 pieces

|

|

| Max branch thickness |

2 cm

|

0.79”

|

| Driving speed up to |

2.5 km/h

|

1.55 mph

|

| Required hydraulic connections |

1 x double acting + 1 x drain

|

|

| Required oil flow |

25 l/min @ 190 bar

|

6.6 gpm @ 2756 psi

|

| Weight |

100 kg

|

220 lb

|

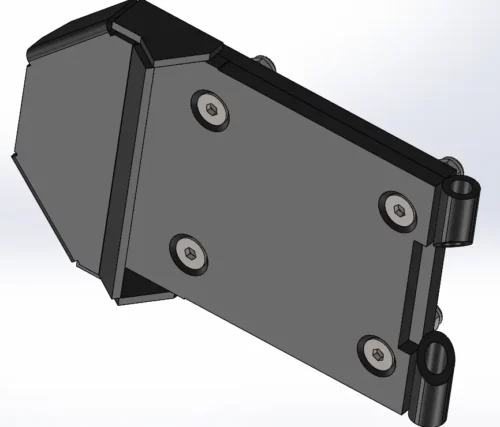

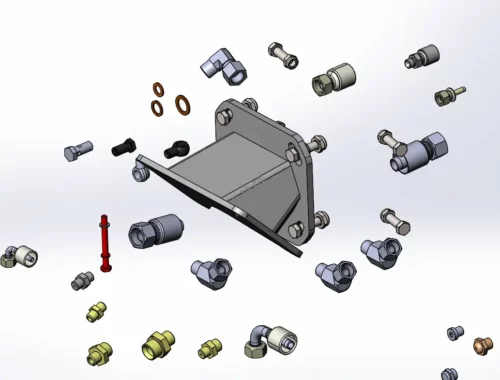

Under the hood

RC 102

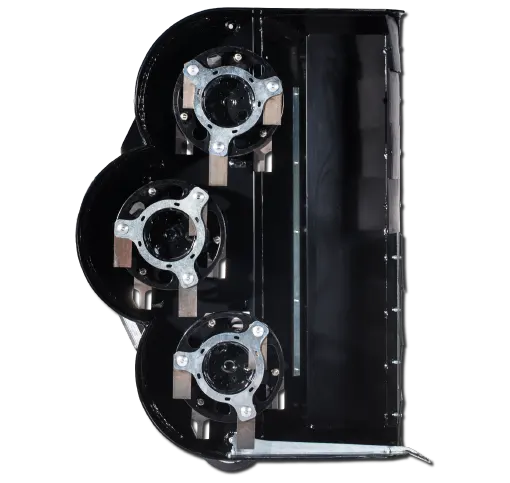

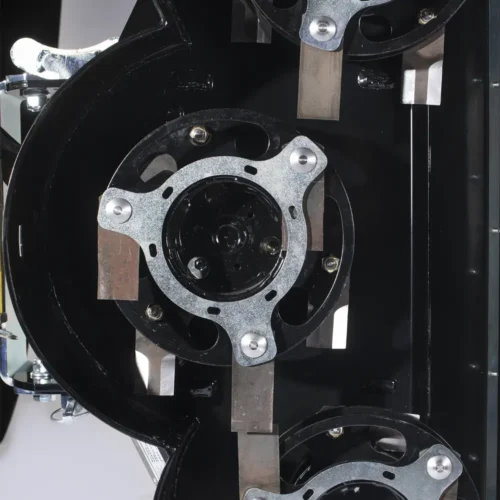

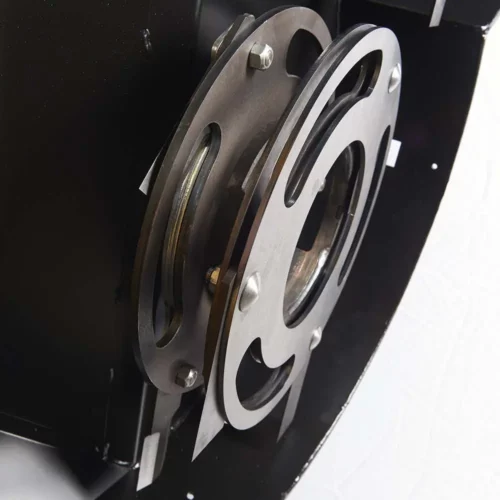

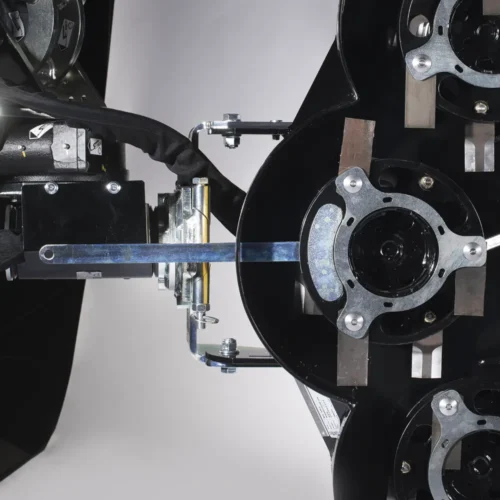

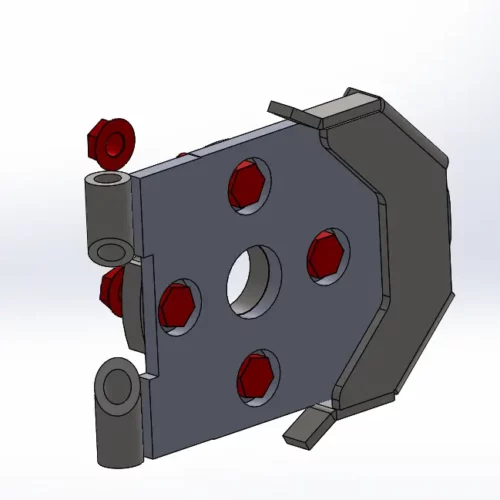

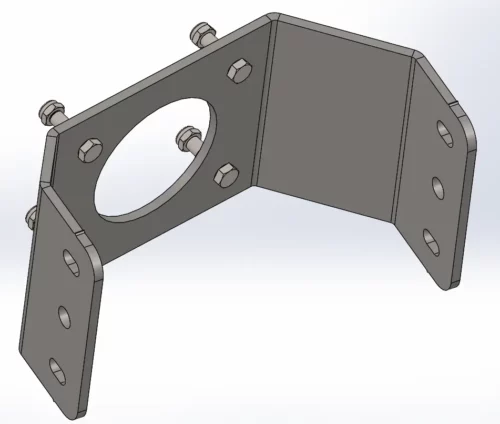

Blade system with double cutting depth

3 blades in two levels per rotor

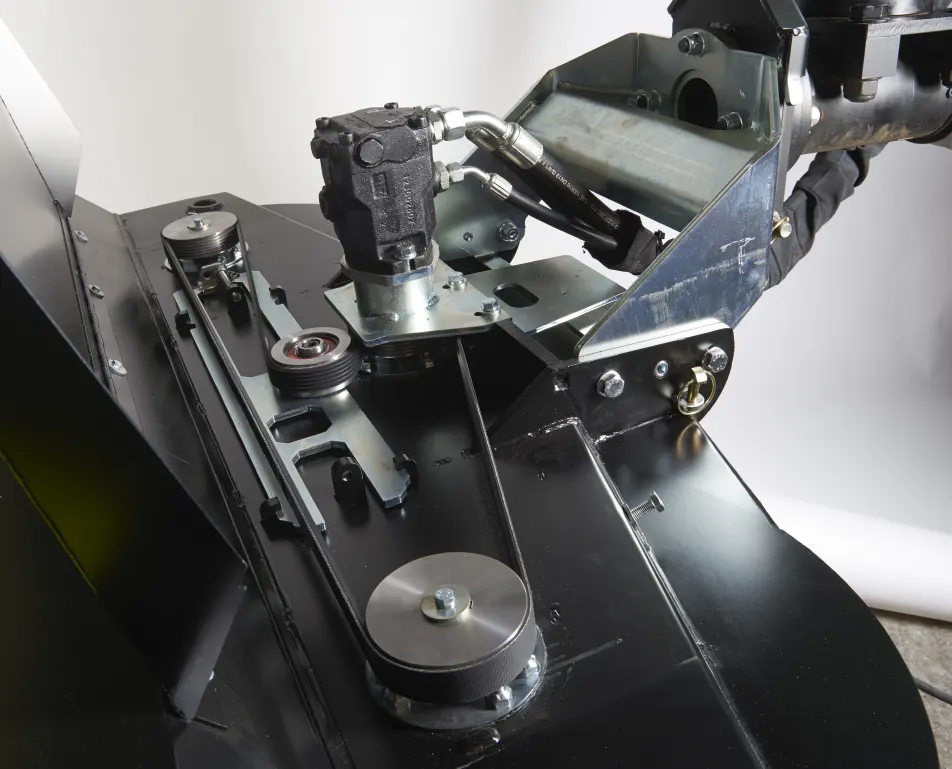

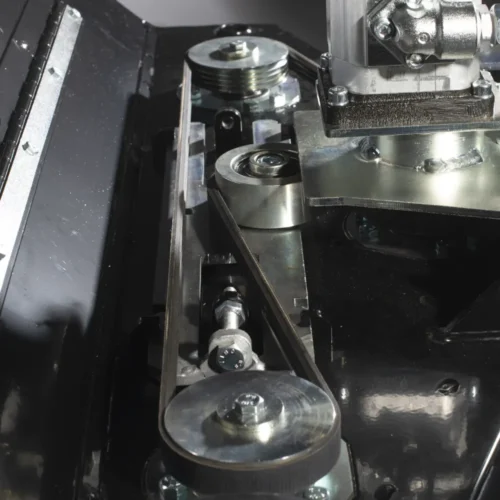

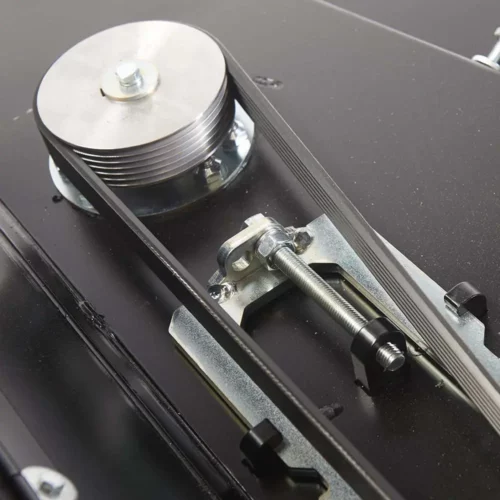

Power band belt drive

Maximum power transfer

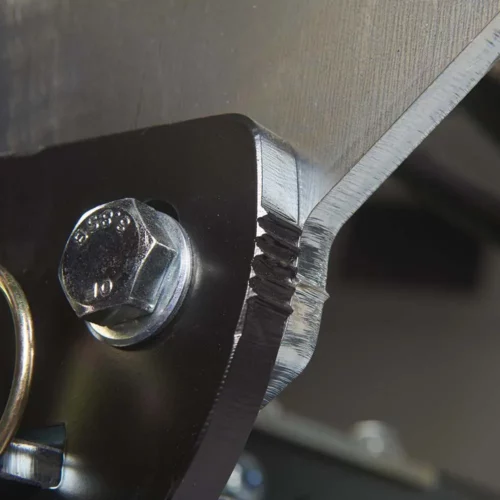

Free-swinging blades

The blades rotate backward in case of an overload

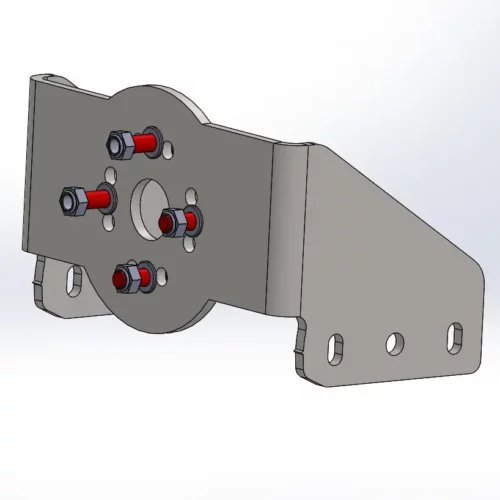

Gradual cutting angle setting

Cut both vertically and horizontally

Branch guider

Provides an even intake of branches

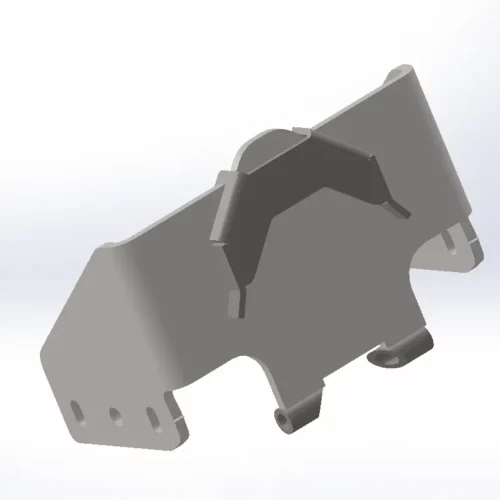

Accessibility

Easy to access the belt drive for maintenance

Rubber flap kit

Minimize flying materials during use

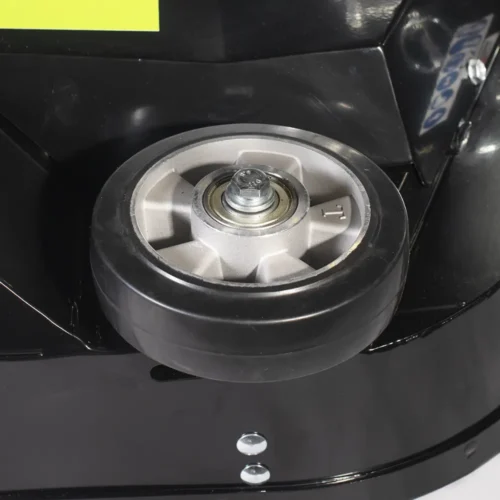

Support wheel

Avoid hitting the ground with the machine

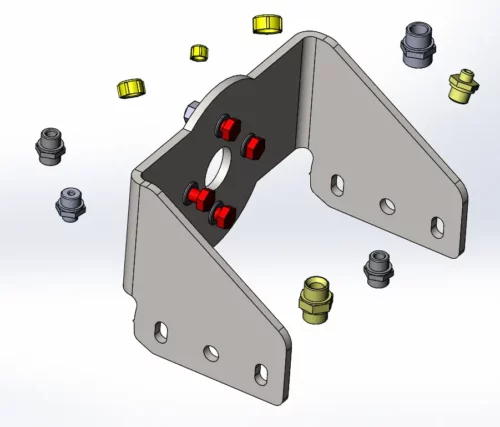

Blade system

Efficient blade system with double cutting depth

The RC 102 has 3 rotors with a double blade system. There are 3 blades at each level per rotor. The lower blades cut branches up to 2 cm (0.79”) in thickness and the upper ones ensure that the material is shredded to tiny pieces.

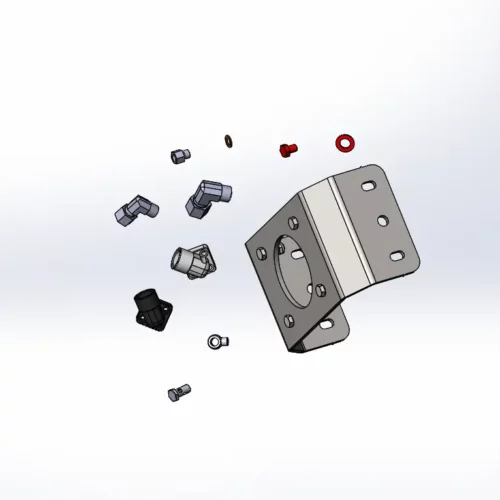

Power Band belt drive

Easy access with plenty of space

Achieve maximum torque transfer due to the large surface on the belt pulley.

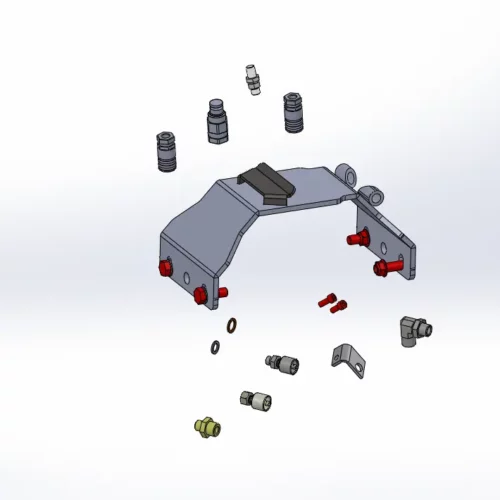

Equipment overview

| Hydraulic motor |

|

| Power Band belt drive |

|

| Belt tightener |

|

| Blade system with double cutting depth |

|

| Free-swinging blades |

|

| Tool for easy change of blades |

|

| Gradual cutting angle setting |

|

| Branch guider |

|

| Support wheel |

|

| Rubber flap kit |

|

| Enforced body |

|

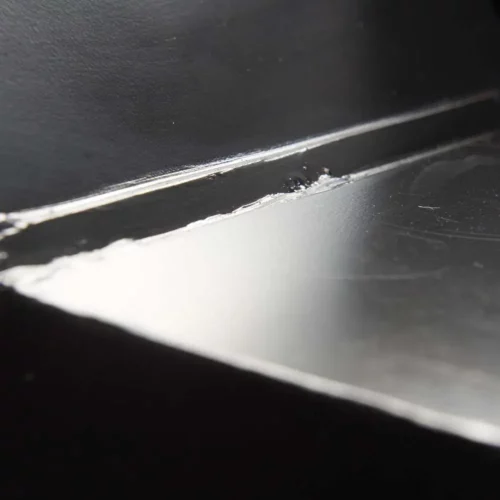

| Smooth surface |

|

| Easy access to the belt drive |

|

| Performance enhanced cutting angle |

|

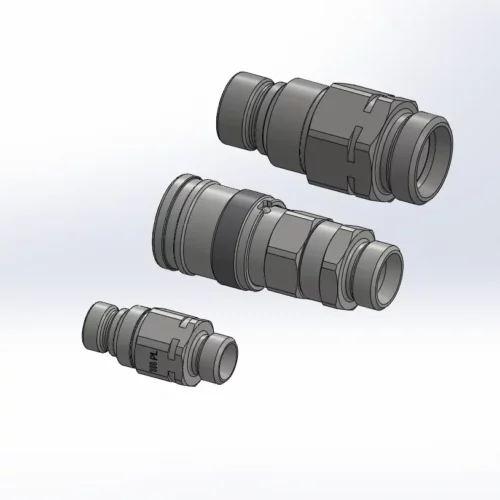

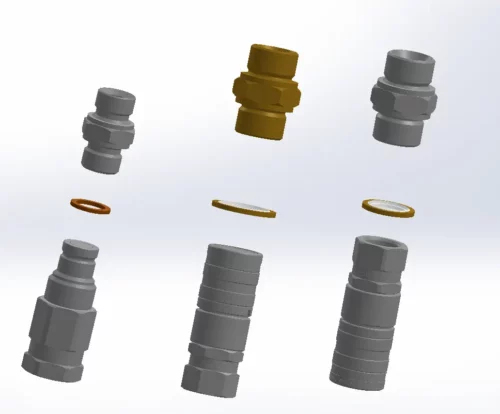

| Quick release, hydraulic |

|

| Quick release, mechanical |

|

Mounting options

↔️ Arm: 1.8 m (5'11")

⚙️ Tools: 6

↔️ Arm: 1.8 m (5'11")

⚙️ Tools: 6

↔️ Arm: 2.2 m (7'3")

⚙️ Tools: 11

↔️ Arm: 1.4-2.2 m (4'7"-7'3")

⚙️ Tools: 11

↔️ Arm: 3.3 m (10'10")

↕️ Arm: 3.1 m (10'2")

↔️ Arm: 3.3 m (10'10")

↕️ Arm: 3.1 m (10'2")

↔️ Arm: 3.3 m (10'10")

↕️ Arm: 3.1 m (10'2")

↔️ Arm: 3.3 m (10'10")

↕️ Arm: 3.1 m (10'2")

↔️ Arm: 4.3 m (14'1")

↕️ Arm: 4.1 m (13'5")

↔️ Arm: 4.3 m (14'1")

↕️ Arm: 4.1 m (13'5")

↔️ Arm: 4.3 m (14'1")

↕️ Arm: 4.1 m (13'5")

↔️ Arm: 4.3 m (14'1")

↕️ Arm: 4.1 m (13'5")

Models

RC 102 (25 l/min), left handed

RC 102 (25 l/min), right handed

Related products

↕️ Range: 1.3 m (4'3")

🌳 Limb: Ø 3 cm (1.2")

↕️ Range: 1.6 m (5'3")

🌳 Limb: Ø 4 cm (1.6")

↕️ Range: 1.7 m (5'7")

🌳 Limb: Ø 6 cm (2.4")

↕️ Range: 2.1 m (6'11")

🌳 Limb: Ø 6 cm (2.4")

↕️ Range: 2.4 m (7'10")

🌳 Limb: Ø 6 cm (2.4")

↕️ Range: 1.5 m (4'11")

🌳 Limb: Ø 4 cm (1.6")

↕️ Range: 1.8 m (5'11")

🌳 Limb: Ø 4 cm (1.6")

↕️ Range: 2.1 m (6'11")

🌳 Limb: Ø 4 cm (1.6")

↕️ Range: 2.4 m (7'10")

🌳 Limb: Ø 4 cm (1.6")

FAQ

We sell our products through a network of dealers. We encourage you to contact your local GreenTec dealer for more information.

If you need any sales advice or cannot find a dealer near you, feel free to contact us on telephone: +45 75553644 or e-mail: sales@greentec.eu

We are available Monday to Thursday from 08.00 - 16.00 CET and Friday from 08.00 - 15.00 CET.

All products are manufactured in Denmark at our production facilities which consist of 5,500 m². We have employees welding components, assembling machines and checking features before the product is shipped to the customer.

We love to give customers a tour of our factory. If you are planning a visit to Denmark, you can schedule an appointment through e-mail: sales@greentec.eu

Our dealers sometimes do demonstrations. You must contact your local GreenTec dealer and ask if they have any upcoming demonstrations.

You cannot rent GreenTec machines directly through us.

We encourage you to contact your local GreenTec dealer to get a list of customers that might be able to offer this service.